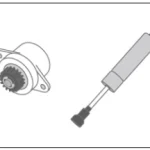

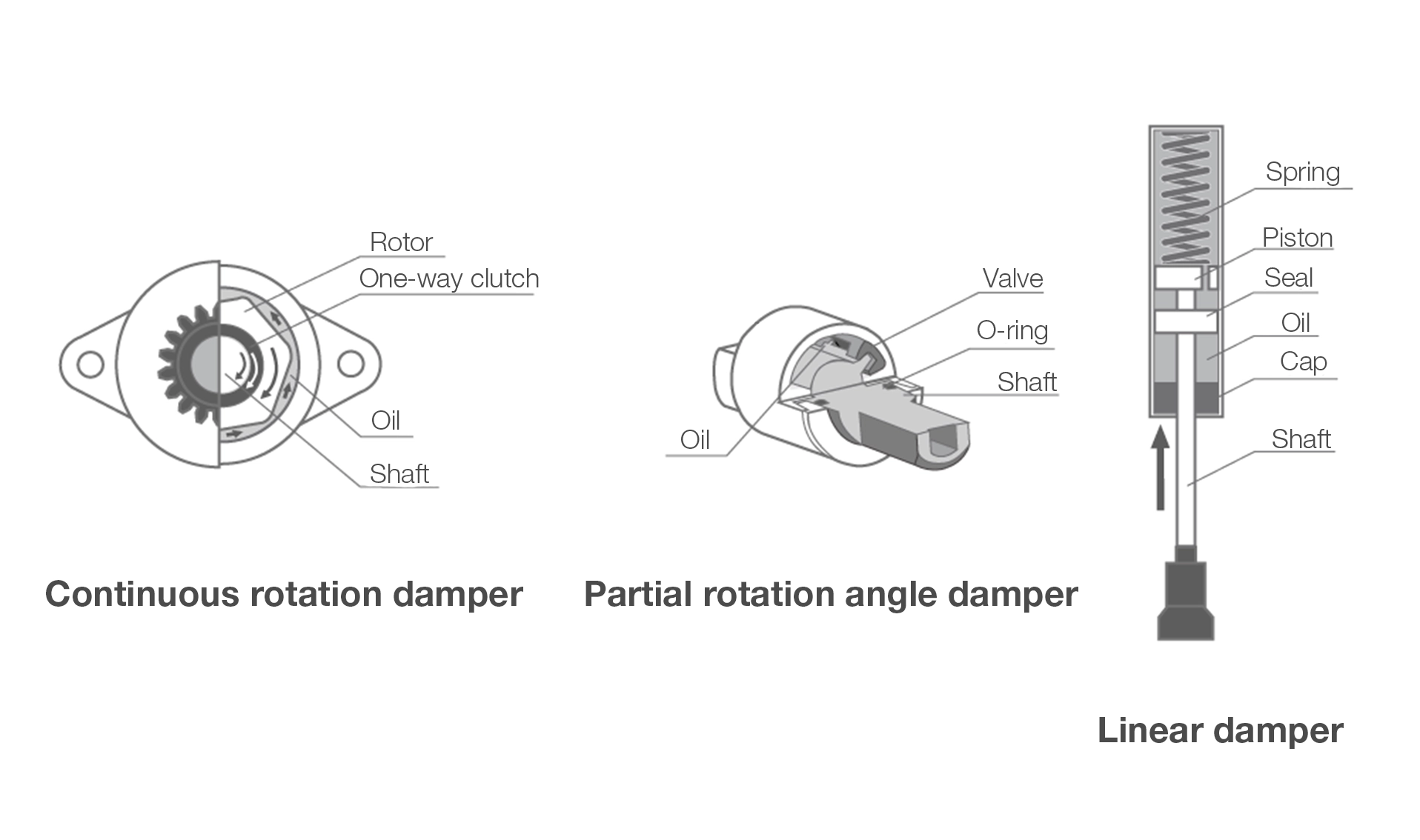

A rotational damper and a linear damper share a common feature in that they both use hydraulic pressure and generate shock absorbing capacity by oil flowing in a narrow channel, but the difference is that a rotational damper obtains shock absorbing capacity by rotating a shaft, whereas a linear damper obtains shock absorbing capacity by linear motion.

A rotational damper is a component that slowly closes a toilet lid, and so on by generating torque through the viscous resistance of oil or hydraulic pressure generated by rotating the internal mechanism. There are two types of rotary dampers with different structures, one is a continuous rotation damper that obtains shear resistance by stirring a viscous body while maintaining a certain space, and the other is a partial rotation angle damper that obtains high hydraulic pressure by intentionally pouring a viscous body into a narrow area. On the other hand, a linear damper is a mechanical component that slowly closes a sliding door, and so on, using a compressive force in a linear direction. Rotational dampers rotate in a circumferential direction, while linear dampers can only be moved in a linear direction, so it is necessary to select a product suitable for the damper’s operational image and mounting space. Depending on the mounting method, the rotary damper can be changed from rotational to linear motion.

In this article, we will explain the difference in mechanism between a rotational damper and a linear damper and suitable application examples for each type of dampers.

Contents

Difference in mechanism between a rotational damper and a linear damper

Rotational dampers are divided into continuous rotation dampers that use viscous resistance and partial rotation angle dampers that use compressive force. Continuous rotation dampers exert torque by stirring oil, whereas partial rotation angle dampers are designed to exert torque by flowing oil through a narrow channel. In both cases, rotary dampers tend to have fewer parts than linear dampers.

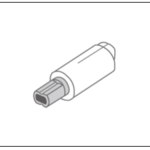

On the other hand, linear dampers which use compressive force, require additional parts that rotational dampers do not have, such as springs, so they tend to have more parts than rotational dampers. A spring also plays a role in returning a pushed shaft to its original position and also acts as a resistor by itself. Linear dampers can absorb relatively larger forces, but in exchange, they require more stroke to push oil, which tends to increase their overall length.

Suitable application examples for a rotational damper and a linear damper

Rotational dampers are suitable for all products that open and close with a center of rotation and require high damping force when closing, such as toilets, pianos, and trash can lids that use hinges. Since it is simply attached to the rotational axis, it can be slowed down by a simple mechanism. The product is built into the center of rotation so that it is not visible on the external appearance, thus keeping the mounting area neat and clean and not spoiling the external design. Rotational dampers are also suitable for applications where linear dampers cannot be used due to restrictions on axial dimensions.

When installing a linear damper, it is difficult to install it on the rotational axis because it tends to be longer in overall length, so it must be attached like a stay at a different position from the rotational axis. Therefore, it is necessary to consider the mounting position and the addition of mounting parts. In addition, depending on the installation method, the appearance may be affected and design issues may occur. However, if the rotational axis is restricted and there is no space to install a rotational damper, a linear damper may be more suitable.

Linear dampers are suitable when mounted on products with linear motion, such as sliding doors, desk drawers, and automobile and motorcycle suspensions. Linear dampers are used for products that are not connected to the center of rotation of the lid and are mainly integrated within a three-point link, so they are exposed on the product exterior but do not have a problem with a design or safety. Because they can exert more shock absorbing capacity than rotational dampers, they are used in places where large forces are generated, such as sliding doors. Also, it is suitable for applications where the outer diameter of a rotational damper would be too large, resulting in a poor appearance of the mounted product, or for applications where the rod of a linear damper does not get in the way.

Summary of what is a rotational damper? | the difference between a rotational damper and a linear damper

Linear dampers are often used for linear motion, but if space or motion is limited, rotational dampers can also be used. TOK only offers rotational dampers, but please see this article for information on using rotational dampers in a linear direction.

TOK calls rotational dampers “rotary dampers” and you can find our lineup of rotary dampers here.

Please wait until the contact form is indicated.

If you cannot find the contact form in spite of waiting, please let us know from this link.