Contents

1.Rotary damper with a relative | Customized example

Hinge with a rotary damper | Minor change for the shape

We can manufacture hinge cases as your requested shape and provide damper hinges with built-in rotary dampers.

Additionally, the TD27/TD28 series already has brackets and can be supplied in hinge form.

There is a page in the catalog that introduces the bracket for TD27/TD28.

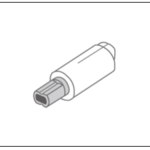

Rotary damper with a attachment for making thicker shaft

There are rare applications in which our plastic rotary dampers lack shaft strength.

When a customer needs more strength for rotary dampers, we recommend our customers to change from TD99 series (made of resin) to TD56 series (made of die casting).

(TD56 series has a thin shaft, making it suitable for mounting on relatively thin objects).

The mounting dimensions of TD56 will be the same as those of the TD99 by an attachment is mounted on the shaft. Therefore, it is easy to improve the strength of the shaft.

(Not listed in our catalog, but attachments are available.)

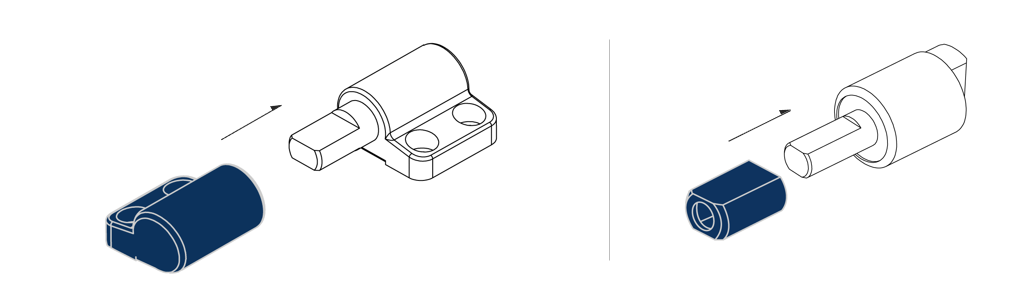

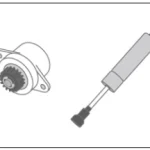

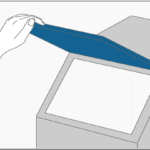

Rotary damper with a shaft detachable part

We cannot only supply rotary dampers, but also design and produce relative parts and provide them as a unit.

For example, there is a shaft quick attaching and detaching device called SR14 that is combined with the TD100 series.

When we provide the rotary damper with SR14, the rotary damper can be easily attached and detached from the separately prepared metal shaft (which we can also provide).

On the situation for removing the toilet seat to clean, this detachable device allows the toilet seat to be removed with a single push.

The toilet seats is easy to attach the toilet bowl by simply press the hole in the SR14 into the shaft.

We have many cases of custom-made parts being assembled and provided to standard products, Please contact us if you have any requests.

Partial customized rotary damper | Specialized housing

We can provide custom-designed housing shapes using standard rotary damper parts.

A rotary damper can be changed a housing shape so as to be easy to install for a customer, if you allow us to keep the internal design.

Our standard products, the TD136, is a newly manufactured housing only, This rotary damper is based on the TD130.

Please note that a mold manufacturing fee will be charged when a housing is custom-made.

Customized products will not be sold to the other customer, so the lead time may be generally longer than our standard products.

For the lead time shorter, it is necessary for you to share with us your forecast and demand information.

Partial customized rotary damper | Specialized shaft

We can produce rotary dampers with the customized shafts by using parts of our standard products.

For example, there is a custom-made product that utilizes parts from the TD99 series, with only the shaft having a custom shape to prevent accidental assembly when the customer mounts the rotary damper.

As with custom-made housings, rotary dampers with custom-made shafts are required a mold and will not be sold to the other customers, which can result in long lead times.

(Lead time may be shortened depending on prior information.)

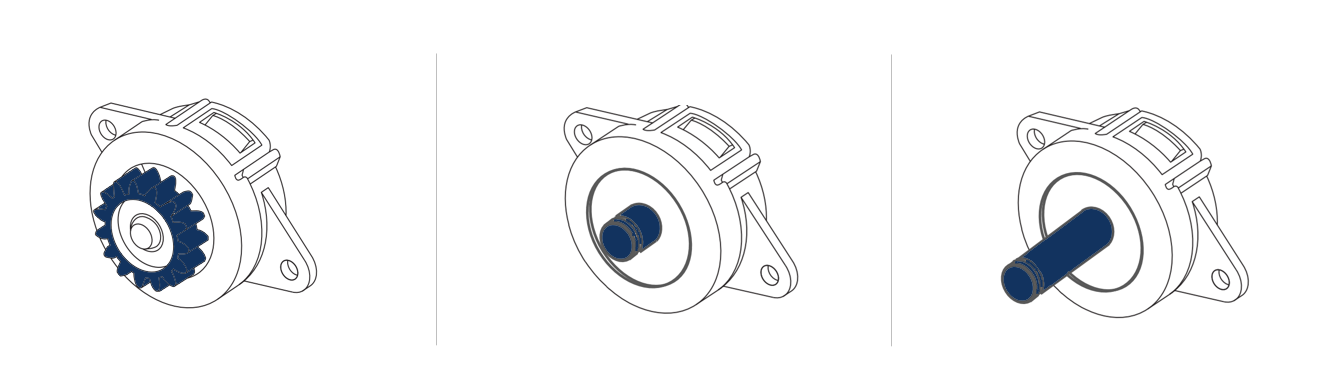

Continuous rotation damper with customized gear

Our company can provide rotary dampers with custom gears made of other materials or specifications.

For example, a rotary damper gear is used as an idler, even if the damping torque is enough, the strength of the gear itself may be needed.

In such cases, gears conventionally produced with POM resin can be replaced with sintered gears.

(If sintered gears are manufactured, the customer will be charged for the cost of manufacturing their own molds.)

We can also provide custom-designed gear specifications (module, number of teeth, tooth width, etc.) without changing the gear material.

This also requires the cost of making a dedicated mold.

Continuous rotation damper with no provided the gear

Continuous rotation angle type of rotary dampers in our catalog products are basically supplied with gears attached, but can be provided without gears when a customer makes their own gears or dedicated attachments.

In our products, “No gear products (products provided without gears)” are those with “…(G-L)” added to the latter half of the product name.

Continuous rotation damper with specialized shaft

The length and shape of the shaft for gear mounting can be changed as requested.

It is often difficult to change the shaft diameter because we utilize parts from our standard products except for the shaft.

The shaft can be changed the length, the D-cut shape, and the groove shape for the retaining ring.

When customizing a shaft shape, it is often offered without gears.

The shafts are usually made by rase cutting process because it is important accuracy for the shaft.

If shafts are made by some tooling, it shall be needed grinder process.

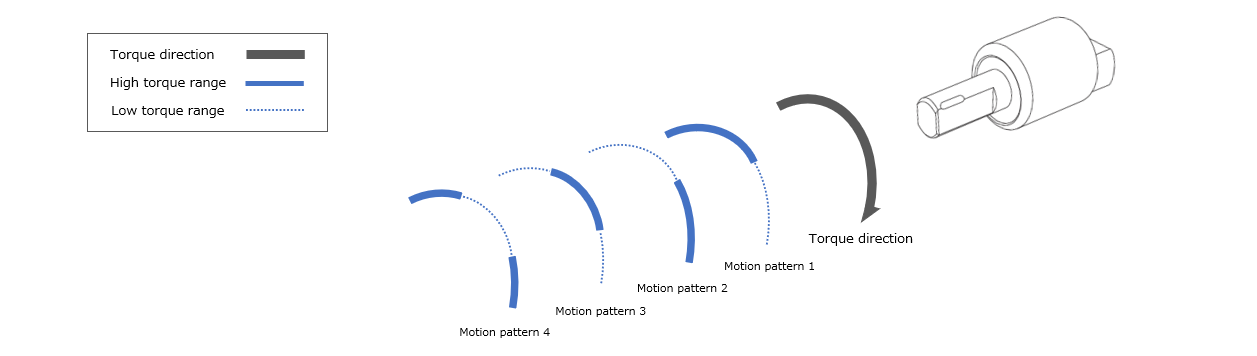

Rotary damper with customized impression of a lid closing speed

The the partial rotation angle damper does not have a constant torque but has a torque characteristics so as to match a lid. When a lid close horizontally, the damping torque must be designed to gradually increase, and when it closes vertically, the damping torque must be designed to gradually decrease.

(For more information, please refer to the article ” Select the rotary damper by the movement “)

For example, when the TD99 series is used for a lid that closes horizontally, it is set to close slowly from around 30° before.

On the other hand, if you want a damper so that a lid closes slowly all operation angle, we can produce it by a custom-made shaft.

Custom-made shafts are charged for molds cost.

Rotary damper with no filling oil for damping

When a customer has two kinds of products, for example, one has a lid slow-down mechanism, two has no slow-down mechanism, we can provide a rotary damper with no generate damping torque.

We refer to those that do not generate damping torque as “0 (zero) K”.

By supplying this rotary damper, customers can assemble products with and without lid slow-down mechanisms using the same parts.

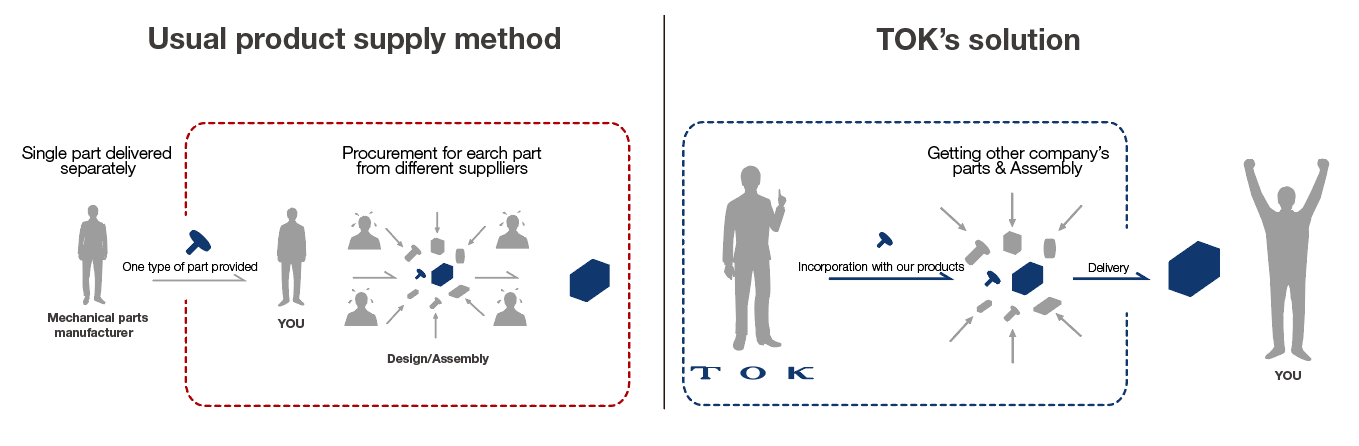

A one-stop shop for custom dampers

TOK, Inc. has a possibility to provide products as one-stop resource.

If you have a design issue, TOK, Inc recommend a discussion before you make a prototype, because TOK can propose suitable design to use rotary dampers.

By supplying simple custom-made products that standard components, it may be possible to create a rational design that eliminates unnecessary parts.

Rotary damper and provision of related parts for a damper performance

When TOK, Inc. receives a special order for a rotary damper, TOK staff will interview a customer to the extent that a customer can disclose.

TOK will naturally be able to make proposals for peripheral design.

Sometimes, small assembly errors or gaps may cause rotary dampers to fail to perform properly, resulting in large individual differences in the slow-down mechanism during mass production.

In order to reduce product performance variations due to such assembly, we sometimes propose related parts for rotary dampers that customers need and purchase them as a bundle with the rotary damper.

When you would like to flip up the lid, we can propose springs, covers, and press parts (sheet metal) to be used together with the rotary damper, which can be purchased as a bundle.

Also, by purchasing them as a unit, we can simplify the mounting of the rotary damper on the customer’s product, this will simplify the mounting of the rotary damper on the customer’s product and realizes the good slow-down operation of the application.

Purchasing a bundle with peripheral parts is also beneficial to the supplier because it simplifies the process for the parts manufacturer.

5. Contact us

TOK, Inc. introduced a simple custom-order example that utilizes conventional parts since many customers assumed that they have to choose a rotary damper from the catalog.

Since simple custom-made production has the advantage of requiring only minimal investment, we highly recommend that you consider this before considering complete custom-made production (all parts are newly designed and made-to-order).

If you are having trouble selecting a rotary damper or feel that catalog products are not user-friendly, please contact us.

The following steps will guide you to the most suitable product.

First step: We introduce you to catalog products that we believe best suit your needs.

Second step: If we cannot find the best product in the first step, we will propose a simple custom-made design.

Third step: We develop a completely custom rotary damper.

We would be happy to assist you in providing your products from the design stage.

If the form does not appear after a few moments, please contact us from here.

We would be happy to assist you in providing your products from the design stage.