The torque of a rotary damper depends on the application in which it is mounted.

In this article, we offer some tips to help you decide on the torque when you are choosing a rotary damper.

Application weight

Heavy applications

To withstand the size and weight of the application, you will need a high torque rotary damper.

If a low torque rotary damper is used here, the application will move too fast and it will be dangerous.

Examples of TOK products are TD22, TD42, and TD129. These rotary dampers are made of zinc die cast and have high rigidity.

Light applications

If the application is light, a low torque rotary damper should be used because it is not subjected to much load from the application.

If a high torque rotary damper is used here, the application will not move or will move very slowly.

For TOK products, we recommend TD73, TD75, and TD101. These products can be installed in tight spaces due to their small diameter.

Application size

Long applications

A high torque rotary damper should be used because it requires high torque to withstand the length of the application.

If a low torque rotary damper is used here, the application will move too fast, close too quickly, and be dangerous.

Short applications

If the application is short, a low torque damper is sufficient.

If a high torque rotary damper is used here, the application will stop in the middle and can’t move or move very slowly.

Center of gravity of applications

When the center of gravity of a heavy application is located closer to the center

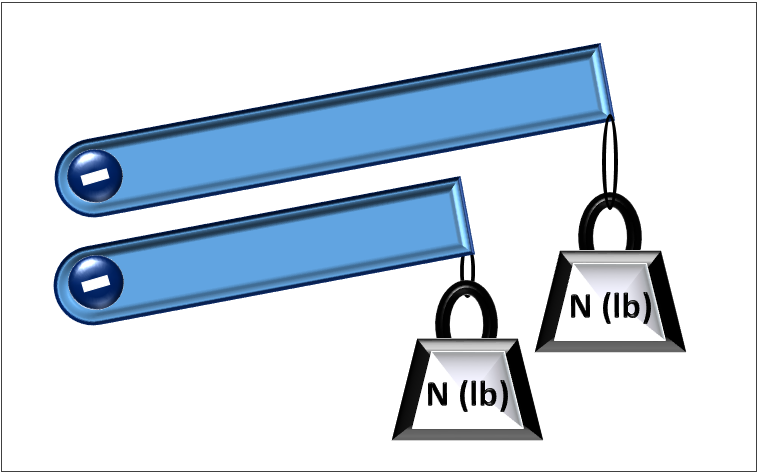

When using a rotary damper for heavy applications, it is recommended to use 2 rotary dampers.

This is because if only 1 rotary damper is used, the application will be twisted.

Because of the close center of gravity, even if 2 rotary dampers are used, the difference in torque is small, so rotary dampers with the same torque can be used.

When the center of gravity of a heavy application is off-center

If 2 rotary dampers are used, too much load will be placed on one of them due to the unbalanced center of gravity, so you need to use a rotary damper with a lower torque on one side and a rotary damper with a higher torque on the other side.

If the center of gravity is shifted, the torque must be shifted accordingly.

From these above points, you see that application weight, size, and center of gravity position are important in torque selection.

If you want to learn more, you can do a detailed torque calculation here.

Also, the torque of a rotary damper varies depending on the ambient temperature and rotational speed.

If you do not find what torque you should use, please feel free to contact us.

We will design it according to your application and the environment in which it will be used.

Related Articles

・Rotary damper torque auto-calculation

・Rotary Damper Torque Calculator | One Point Explanation

・Rotary Damper Torque Calculator | For Free Fall

・How to Amplify Torque with Gears When Rotary Damper Lacks Torque