Although the operating principle of rotary dampers is the same regardless of size, the designer’s experience and competence can be important when using a small rotary damper to achieve soft close. Specifically, it is the design capability to identify the compatibility between the small rotary damper and the relative components, and there is an essential point to the usage and selection method.

When we hear from designers who are considering the use of rotary dampers, many of them think as below.

“I want the lid to achieve a soft close with smooth motion, but I want to find a small rotary damper that is as small as possible so that the appearance of the product will not be significantly altered by the mounting of the rotary damper.”

We understand your thought very well, but there may be a slight problem with this approach. This is because there are advantages and disadvantages associated with small size in rotary dampers.

In this article, we would like to provide you with information on how to choose small rotary dampers.

Contents

Advantages of choosing small rotary dampers

The advantage of small rotary dampers is that they are “small” and unlikely to spoil the overall appearance of the product in which the rotary damper is mounted. A small component also reduces the possibility of a large hinge design, resulting in a cleaner appearance.

Another advantage specific to our small rotary dampers is that the color tone is less noticeable after mounting. Two color tones are gray and natural plastic color. Generally, rotary dampers are embedded inside the product and are easily invisible from the customer’s product exterior, but even if they are visible through gaps in the product, they are not noticeable because the rotary damper color is gray. However, since the gray color stands out on white color products, a natural color (white color) version is also available.

Furthermore, there are advantages to the relative parts. Since the rotary damper is small, the mating parts for mounting can also be small in shape, which may reduce the parts production cost.

Disadvantages of choosing small rotary dampers

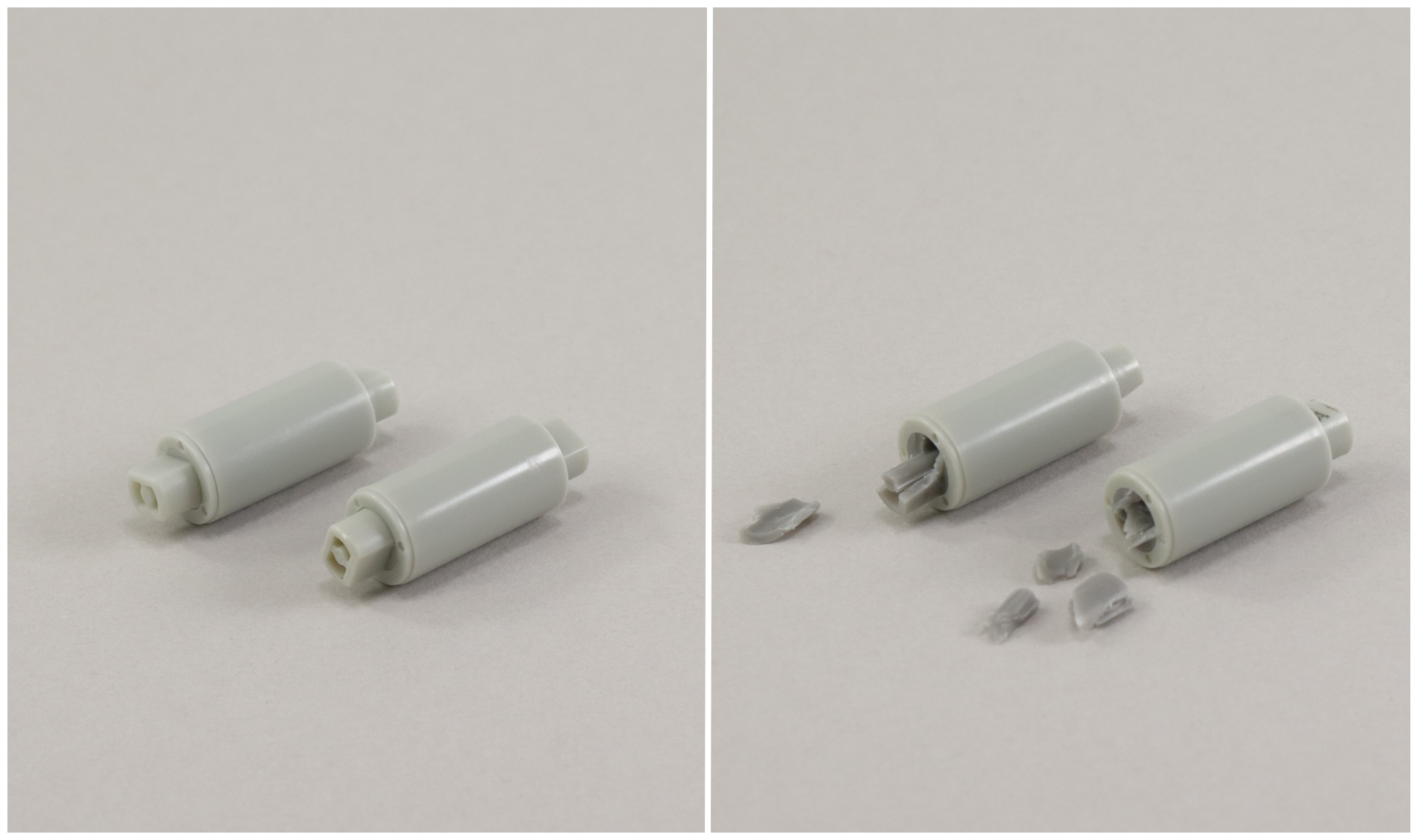

Strength is a disadvantage when selecting a small rotary damper. As you know, torque is determined by the product radius and the working force, so if high torque is required, rotary dampers need to increase the outer diameter or increase the damping force while maintaining a small diameter.

When downsizing, a stopper shape that can withstand damper torque and the weight of the mating parts is required, but a plastic rotary damper may crack when it is used as high torque specifications. To achieve high torque without increasing the size of the rotary damper, we should change materials from plastic to die-cast parts, but even if the rotary damper can be made to high torque specifications, it will be meaningless if it relative part cracks due to insufficient strength of the mating parts. Even if the strength of the mating part can be secured, the design of the mating part (tolerance range) must be precise so that the shape will not collapse due to repeated exposure to damper torque or radial load. Both increased material strength and increased component precision are factors that increase the cost of your product, and in the end, the balance between quality and cost is often lost and mass production is not achieved. Therefore, we believe that downsizing more than necessary should be avoided.

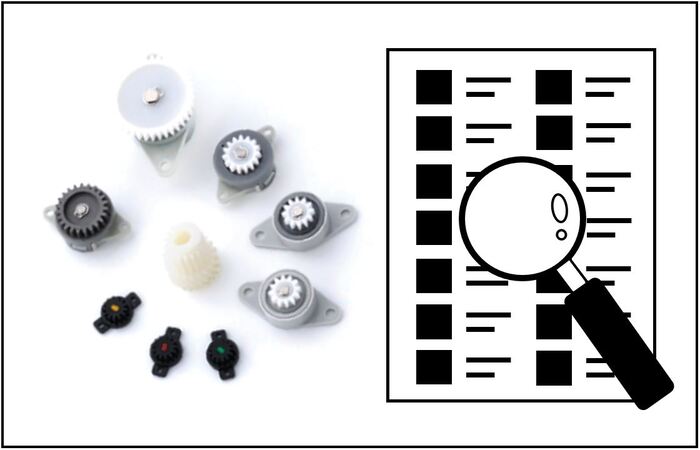

Against this background, we offer a lineup of small rotary dampers made of plastic with an outer diameter of φ11 mm and a maximum set torque of 0.29 N・m (3 kgf・cm), designed to provide reliable soft close and smooth motion in compact spaces.

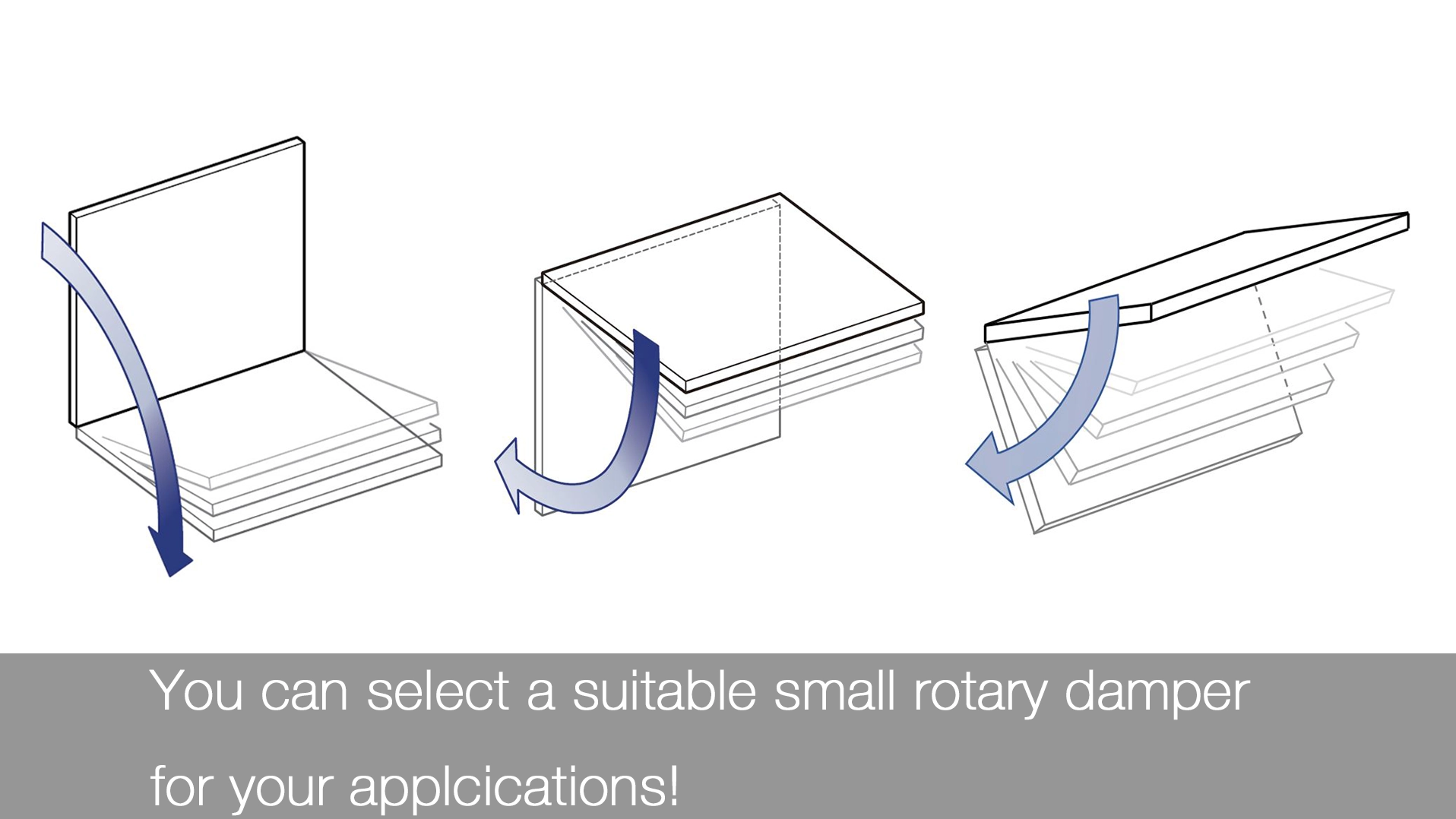

Three ways to select small rotary dampers

The next thing to consider after avoiding high torque specifications and considering a small rotary damper with a maximum torque of 0.29 N・m (3 kgf・cm) or less is the selection of a rotary damper that matches the way the lid closes. Although it is possible to manufacture a rotary damper to special order specifications, producing only the required number of rotary dampers will increase the unit price and require initial investment such as mold fabrication. Therefore, we introduce three types of small rotary dampers that we sell as our standard products.

Small rotary dampers for lids that close horizontally

TD73 is the best choice for lids that close horizontally. TD73 is a rotary damper that exerts high torque about 30° before the lid closes horizontally and closes slowly. Its inconspicuous gray exterior does not interfere with the design of the product in which it is mounted. Torque variations of 0.05/0.10/0.20/0.29 N・m are available, allowing selection according to the weight of the lid. In addition, while the stopper shapes of the fixed and movable sides of a typical rotary damper are often different, TD73 has the same stopper shape on both sides, so depending on usage, there is no need to restrict the insertion direction, allowing for easy and quick assembly. This best-selling product with annual sales of more than 1 million units is used in a wide range of industries.

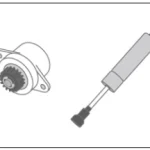

Small rotary dampers for heavy lids that close horizontally or lids close at an angle

-scaled.jpg)

If you want to install a small rotary damper on a lid that closes horizontally, but TD73 does not have enough torque to close the lid quickly, or if you want to install rotary dampers on lids that open and close at an angle, TD148 is the best choice. Not the same as TD73, TD148 is designed to provide high torque throughout the entire opening and closing range of the lid. Therefore, even if it is mounted on a relatively heavy lid for which TD73 does not provide enough torque, it can be moved slowly to the end because it provides a damping effect from the fully open position of the lid. When the lid opens and closes at an angle, the damping torque required for the fully open position, horizontal position, and fully closed position of the lid is not so different, making TD148 with its high torque design for the entire range the right product. TD148 has the same external dimensions (dimensions related to mounting when assembled with the mating parts) as TD73. Therefore, TD148 has no restrictions on the direction of insertion, so it can be assembled easily and quickly, and can also be compared with TD73 by replacing it.

Small rotary dampers for lids that close vertically

TD75 is the best choice for lids that close vertically. TD75 and TD73 are similar in size, but there is a difference in damping torque and operation angle. TD75 has high torque in the horizontal position, where the burden of gravity is greatest, and the damping force is released just before the lid closes. Same as TD73, TD75 has an inconspicuous gray exterior. The torque is 0.10/0.20/0.29 N・m, similar to TD73, but do not forget that the torque design is different. It boasts a durability of 100,000 cycles, and its life expectancy is in the middle class of our rotary dampers.

Usages of small rotary dampers

Here are some usages of small rotary dampers.

Trash cans

If a trash can is not equipped with a rotary damper, the lid will scatter odors from inside the trash can like a hand fan. If a rotary damper is installed, not only the impact noise is prevented, but also the diffusion of foul odors can be suppressed.

Cosmetics cases

When opening a cosmetics case, if the hand slips, cosmetic tools may rustle and, in the worst-case scenario, fly out of the case. By installing a rotary damper, the cosmetics case can move slowly even when the hand is released, giving it a luxurious feel.

Distribution board covers

You may not feel the need to install a rotary damper on the distribution boar cover since it is not opened and closed frequently, but it is expected to avoid the risk of fingers being caught when the lid closes vigorously during inspection or when the breaker is raised or lowered, as well as to prevent the lid from flapping in the event of an earthquake.

Console box

An automotive console box can be used to control the momentum of the lid bouncing up at the push of a button to a comfortable speed, adding a sense of luxury to the motion of the car interior.

Summary of Small rotary dampers | How to use and select dampers

How was it? Did you get an idea of what to expect when considering a small rotary damper? In this article, we have provided the following key points about small rotary dampers.

・Small rotary dampers have the advantage that they do not adversely affect the design of the product in which they are mounted.

・When using a small rotary damper, it is best to use a torque setting that is appropriate for the size of the damper. (High torque in a small size requires higher component materials and assembly precision, which increases costs.)

・Once the optimum torque setting is achieved, the rotary damper should be selected according to the operation angle when closing a lid.

・If cost and delivery time are important, we recommend selecting one of our standard products.

・If performance is important, we recommend that you fabricate a die and make a customized design.

That is all how to use and select damper.

When the design phase, please take advantage of the torque calculation page on our rotary damper website to find the most suitable catalog product. If you are unable to find a product with your desired specifications after searching, or if you are considering or have any questions about customized products, please contact us using this form.

Please wait until the contact form is indicated.

If you cannot find the contact form in spite of waiting, please let us know from this link.