One-way rotary dampers refer to rotary dampers that exert their damper effect in only one direction.

Even if you can use a rotary damper to move an object slowly and safely, you do not want to make manual operations such as opening a shutter or pulling out a take-up cord heavy. A one-way rotary damper is recommended when you want to exert a damper effect in the direction where the object’s own weight is acting or where the object moves vigorously by spring-loaded winding, and not to transmit in the opposite direction requiring manual work.

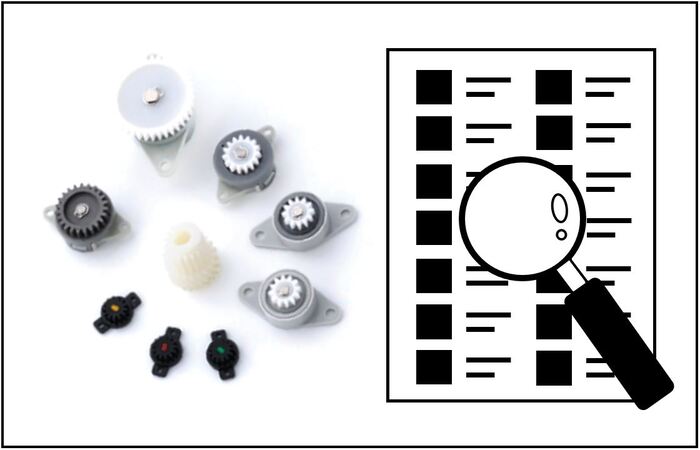

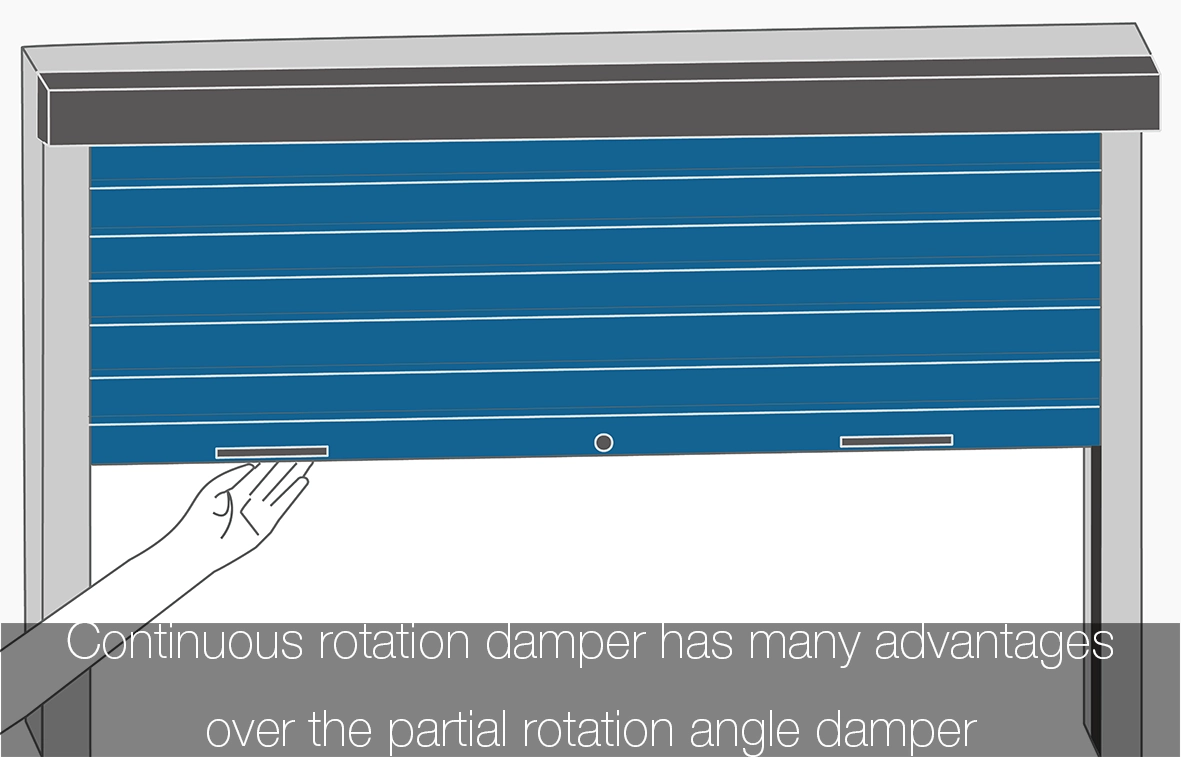

Some one-way rotary dampers are applicable to partial rotation angle dampers with a limited operation angle, but this time we will introduce you to continuous rotation dampers with an unlimited operation angle.

Contents

Features of one-way rotary dampers

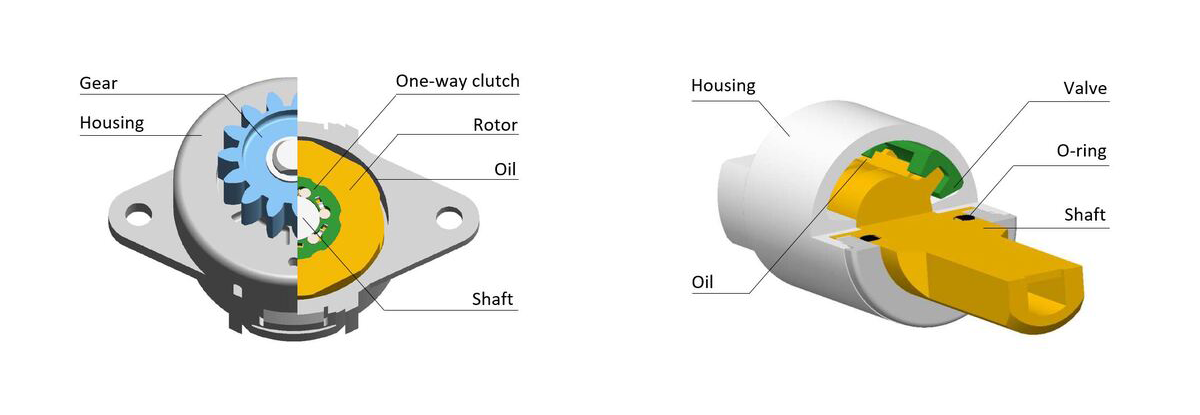

Generally, continuous rotation dampers have a flange on the cylindrical part, and the rotary damper is fixed to the object by the mounting hole on the flange. The shaft is concentric to the cylindrical part and is interlocked with the mating parts by attaching a gear or attachment to the end of the shaft, and damping torque is generated by the rotation of the shaft. Inside the continuous rotation damper is a rotor that is interlocked with the shaft and filled with highly viscous oil, and the shearing resistance of the oil generated when the rotor rotates is the damping torque.

A one-way clutch is needed when rotary dampers are required to allow the rotor to rotate in only one direction.

The one-way clutch can be assembled on the shaft of continuous rotation dampers that supports both directions to allow damping in only one direction. The one-way clutch is built into the rotor to make effective use of the space inside rotary dampers.

Advantages and disadvantages of one-way rotary dampers

Advantages of one-way rotary dampers

No loss of operability or comfort in the free direction

Since the torque in the free direction is small, the lid can be opened with the weight of the lid itself. For example, if the shutter is equipped with the rotary damper, the rotary damper acts to lower the shutter slowly when lowering it. When lifting the shutter, the one-way clutch idles and the damping torque of the rotary damper is not transmitted, and only the weight of the shutter is lifted, so no extra weight is felt.

Good response when the direction of rotation is switched.

One-way clutches have good locking response, so a shaft is connected to a rotor to generate damping torque as soon as the shaft rotation direction changes to the direction that requires damping torque. For example, if a rotary damper is mounted on a keyboard lid, even if user’s hands slip on the keyboard lid while it is slightly raised, damping torque is immediately generated to close it slowly and quietly.

Easy to mount

When mounting a rotary damper with engaging gears, if the assembly phase is out of engagement with the mating parts, it is necessary to rotate the shaft of the rotary damper to engage.

In the case of a bidirectional rotary damper, the shaft must be turned with a force stronger than the damping torque. However, with a one-way rotary damper, the shaft can be easily turned by hand in the direction of rotation where no damping torque is generated, that is, the direction in which the one-way clutch idles, no strong force is required for mounting.

Disadvantages of one-way rotary dampers

Inadequate when torque is required in both directions

Since torque is generated only in one direction, a bidirectional rotary damper must be used if the damper effect is desired in both directions. For example, in an application where you want to suppress the wobble of a dangling heavy object, it will easily move in only one direction.

Delivery time may be longer than for continuous rotation dampers that support both directions.

The increased number of parts required by the one-way mechanism increases the time and effort required for parts procurement, so a longer delivery time of one-way rotary dampers may be required if all the parts are not available.

The diameter tends to be larger when trying to exert torque equivalent to that of partial rotation angle dampers.

Partial rotation angle dampers have a structure that allows viscous oil to flow in a narrow channel, so it can provide higher torque than continuous rotation dampers that only agitate the oil. To make continuous rotation dampers as high-torque specification as partial rotation angle dampers, the outer diameter of the rotor must be increased to gain damping torque. The one-way clutch also requires high torque specifications, so the size of the one-way clutch must also be increased.

Main usages

Finally, here are some examples of the main usages of one-way rotary dampers.

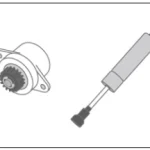

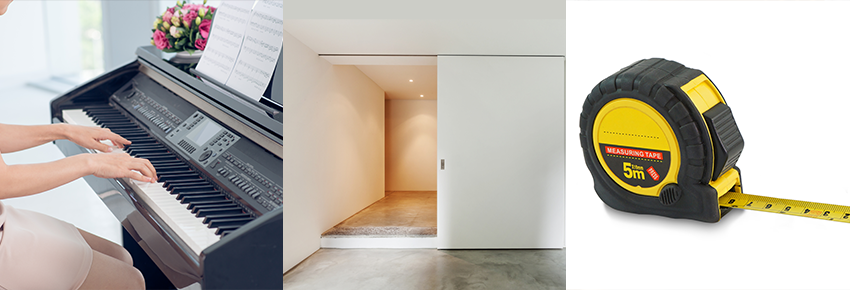

Keyboard covers

If the keyboard cover is an openable type like a piano, the operation angle may be larger than that of a piano. Partial rotation angle dampers cannot be used if the operation angle becomes large. Therefore, a segmented gear is assembled on the side of the keyboard cover, and a one-way rotary damper is installed in the keyboard body so that it engages with the segmented gear, resulting in a responsive and slow closing of the cover and preventing finger slamming.

Sliding doors

With a one-way rotary damper, the door opens with the same force as without the rotary damper, and closes gently with the rotary damper to reduce impact noise.

Steel tape measures

A steel tape measure could cut your hand if you did not hold it down while winding it up to prevent it from winding up too fast when storing it. However, by installing a one-way rotary damper, the tape measure can be lightly pulled out and slowly stowed. This is an effective use for projector screens and other equipment with a mechanism that winds up by spring or other force.

One-way rotary dampers introduced here can also be seen in this video.

Summary of one-way rotary damper | continuous rotation damper

To summarize the contents of this article,

・One-way rotary dampers are equipped with a one-way clutch inside.

・One-way rotary dampers provide good responsiveness when switching the lid open and close, and immediately produce a damper effect.

・Compared to bidirectional rotary dampers, one-way rotary dampers take longer delivery time due to the built-in one-way clutch.

You can use the page where you can calculate the torque when you consider the design. Also, our website only shows standard products, but we can make customized products as well. If you are considering or have any questions about customized products, please contact us using this following form.

Please wait until the contact form is indicated.

If you cannot find the contact form in spite of waiting, please let us know from this link.