Upward opening flaps can be difficult to close to the end by installing rotary dampers.

In many cases, the reason is that rotary dampers are selected incorrectly. So you can open and close lids without any problems by selecting the appropriate rotary dampers for the operation angle.

TOK refers to rotary dampers for vertical closure with an upward opening as vertical use rotary dampers. Our rotary damper website introduces them, and here we explain the selection and effect of vertical use rotary dampers.

Contents

Selecting an incorrect rotary damper affect the motion of an upward opening flap

Gif animation above shows the movement of a horizontal rotary damper mounted on a lid with vertical closure. A lid with vertical closure requires the maximum torque when it is horizontal, but horizontal use rotary damper minimum damper torque, so the weight of the lid cannot withstand gravity, and the lid will fall immediately. On the other hand, when the lid is closing, the damper torque is at its maximum even though it is almost no torque required, so a lid will oppose the movement of the lid to close, and it will take a long time for a lid to close to the end.

When you select an incorrect rotary damper, the torque characteristics required for lids and rotary dampers specifications (torque curve) are mismatched, so lids do not close easily.

We mentioned in the previous article that the maximum moment is reached when lids are closed. It is not surprising that when horizontal use rotary dampers are mounted on lids with vertical closure, they do not close easily.

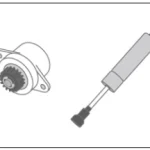

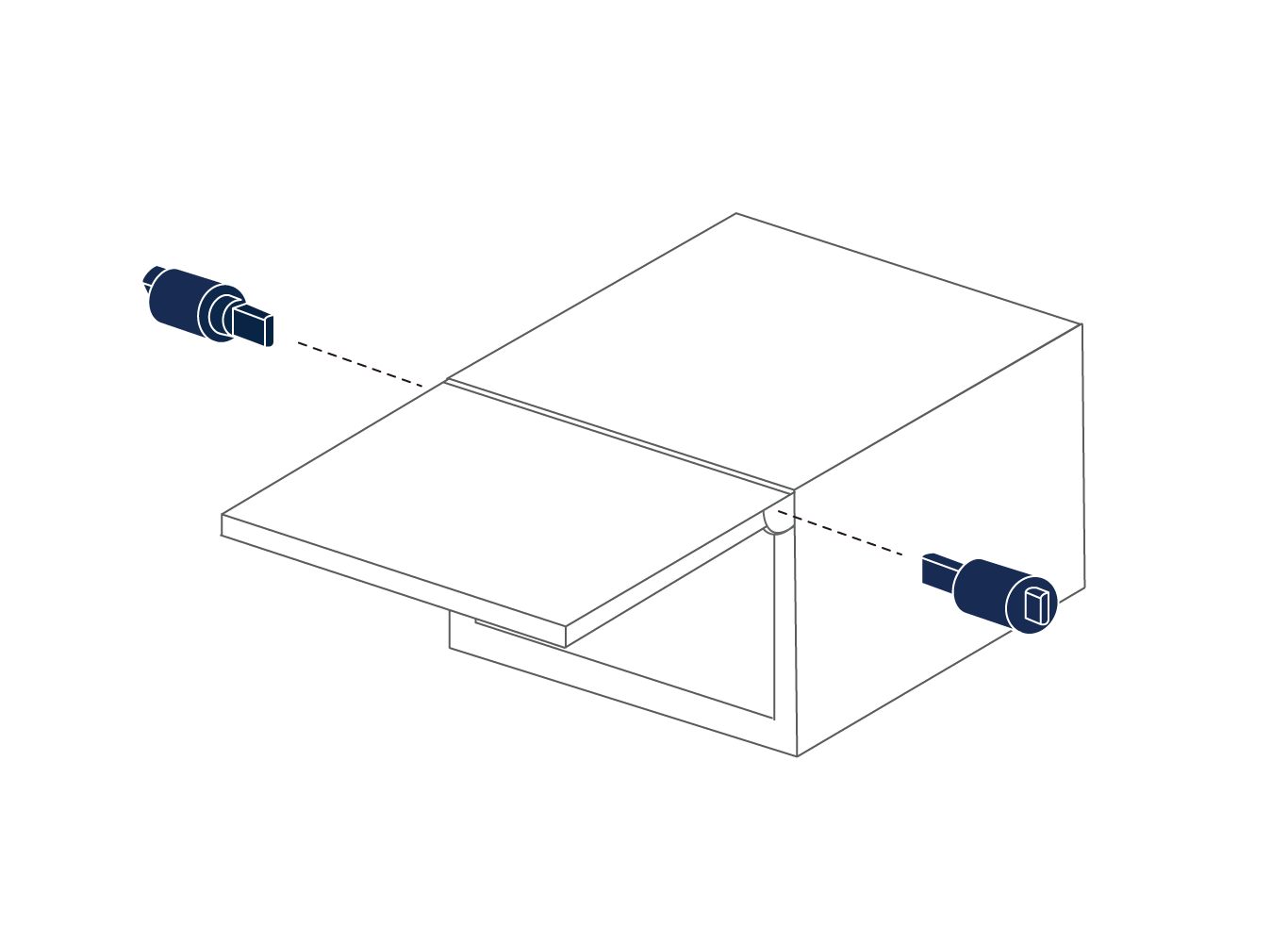

Design considerations when installing vertical use rotary dampers

Although rotary dampers are installed at the center of rotation, the center of gravity of the lid has a significant effect for vertical use rotary dampers. When a lid is hung using the rotary damper mounting position as a fulcrum, the center of gravity of the lid may prevent the lid from closing completely. In this condition, the lid will never close completely whatever you do, so the rotary damper mounting position must be determined so that the lid will close even without the rotary damper. For example, if a rotary damper is mounted on a pet door, the center of gravity must be brought to the center of the door so that it stops straight.

Main usages

Finally, here are some examples of the main usages of rotary dampers.

Pet doors

When vertical use rotary dampers are mounted on pet doors, they can close slowly and without bouncing.

Range hood covers

Heavy lids such as range hood covers can open forcefully. Equipped with rotary dampers, range hood covers can be opened safely. However, you can not install rotary dampers on high temperature part.

Wall-mounted tables and chairs

Wall-mounted tables and chairs are often stored, but they can suffer from impact noise and pinched hands sometimes they are stored. Rotary dampers are mounted on them and operate slowly to prevent impact noise and bounce caused by hit with walls.

All of the usages shown here are heavy products, so we recommend that you use TD99A6B6 series.

This article can also be viewed in this video.

Summary of soft close rotary damper design | How to select it for upward opening flaps

To summarize the contents of this article,

・To follow the required torque change, vertical use rotary dampers are mounted on upward opening flaps.

・When horizontal use rotary dampers are mounted on upward opening flaps, the flaps will not close easily due to torque mismatch.

・The rotary damper mounting position is determined by considering the center of gravity of the upward opening flaps.

You can use the page where you can calculate the torque when you consider the design. Also, our website only shows standard products, but we can make customized products as well. If you are considering or have any questions about customized products, please contact us using this following form. We recommend that you make a mold when you produce the product in large quantities. If you produce the product in small quantities, you should choose the product in our catalog.

フォームが表示されるまでしばらくお待ち下さい。

恐れ入りますが、しばらくお待ちいただいてもフォームが表示されない場合は、こちらまでお問い合わせください。