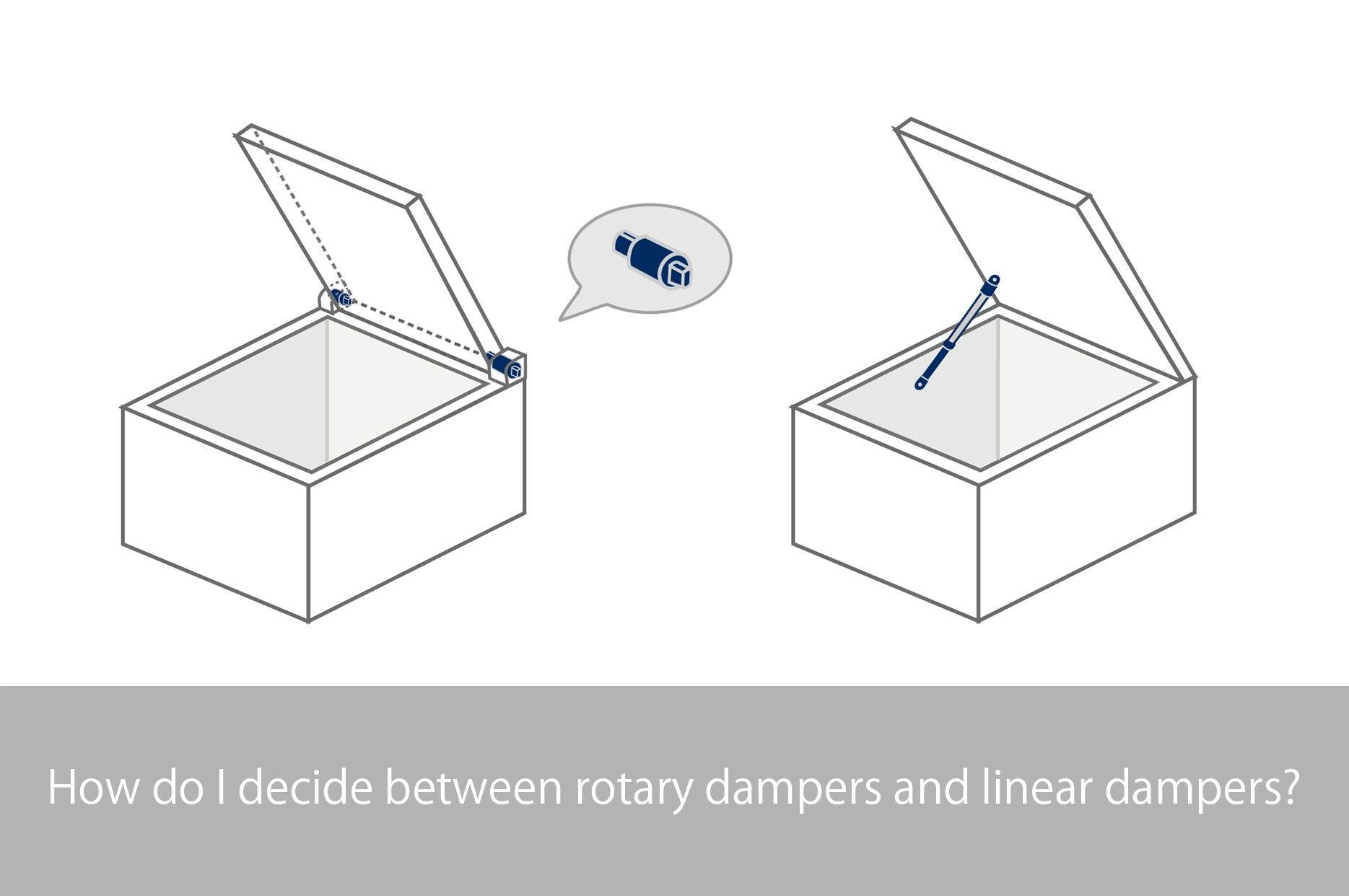

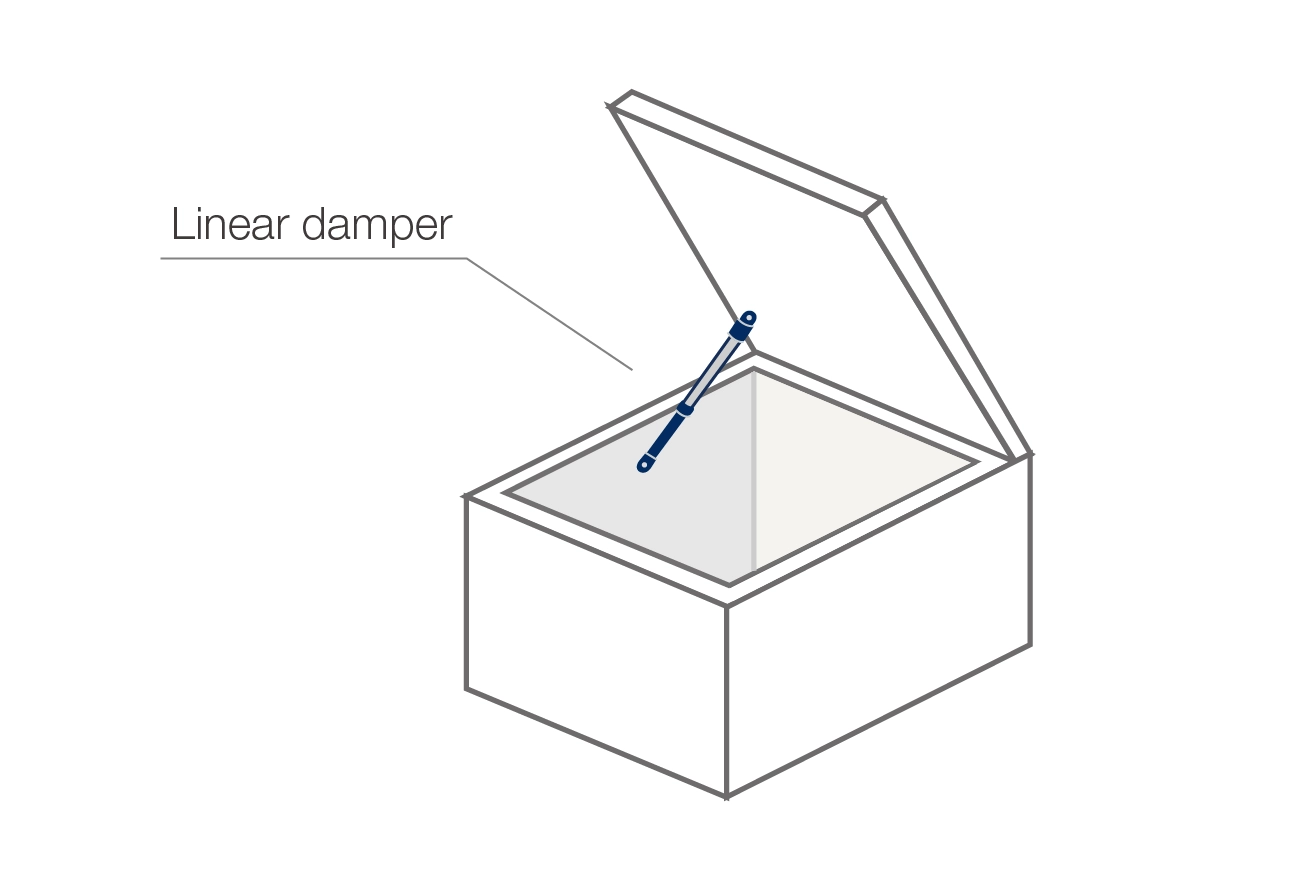

To close the lid slowly, buffer parts such as rotary dampers and linear dampers, gas springs, must be mounted. These buffer parts are selected by taking into account their advantages and disadvantages depending on the application for which they are mounted. In this article, we will introduce the advantages and disadvantages of rotary dampers and linear dampers and the points to consider when choosing between them.

Contents

- Advantages and Disadvantages of Mounting Rotary Dampers to Achieve a Close Slowly Feature on a Lid.

- Advantages and Disadvantages of Mounting Linear Dampers to Achieve a Close Slowly Feature on a Lid.

- Selection Points for Buffer Parts Make Lids Close Slowly

- Summary of Comparison and Selection of Buffer Parts to Make Lids Close Slowly

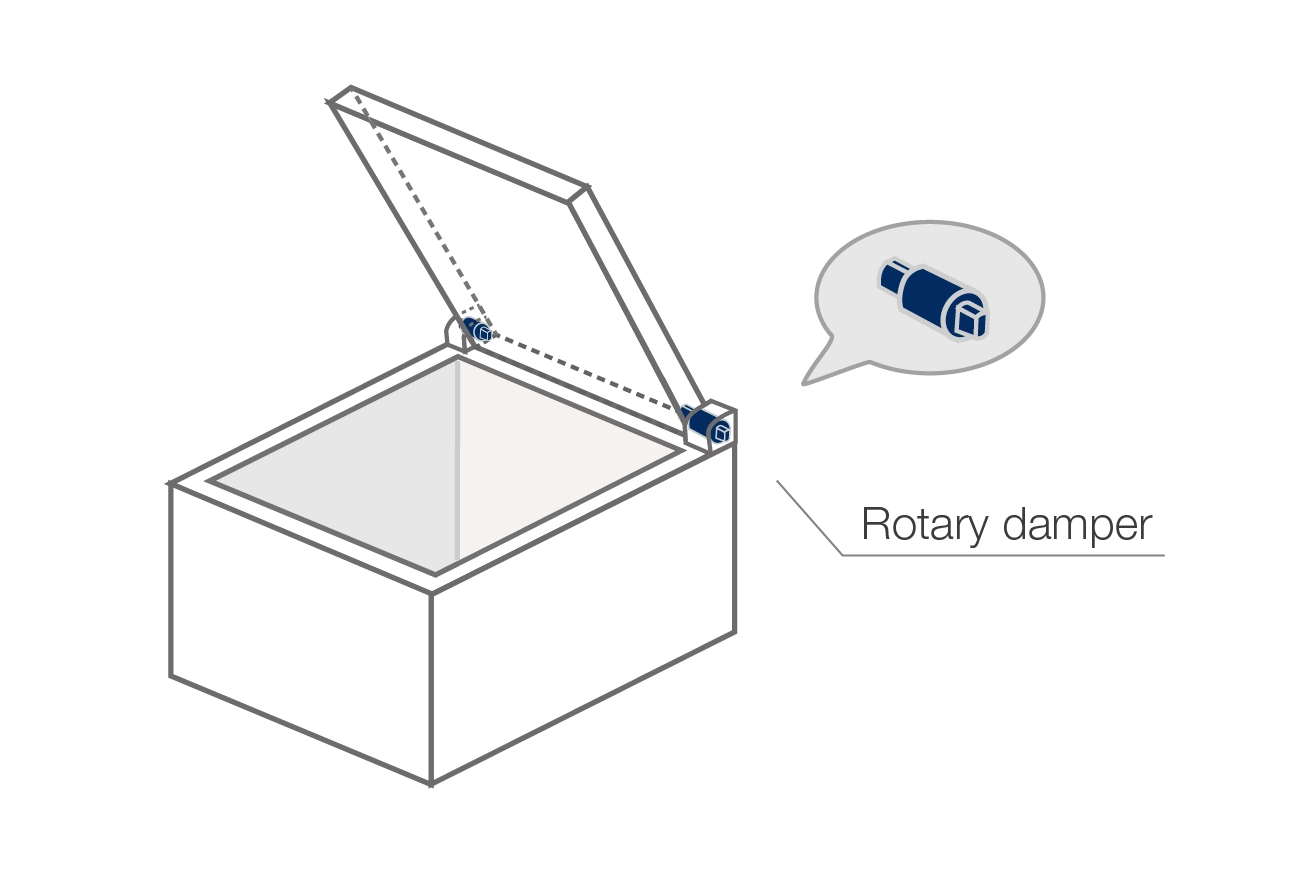

Advantages and Disadvantages of Mounting Rotary Dampers to Achieve a Close Slowly Feature on a Lid.

Advantages

Since rotary dampers are based on a very simple assembly that simply attaches to the center of rotation, the assembly design is easy, even for those who are not familiar with rotary dampers. Also, as it is basically small in size and mounted in an embedded manner, it does not interfere with the exterior design and is characterized by its ease of use. However, the rotary damper to be used changes depending on whether the lid closes horizontally or vertically. For any lid closing, the highest torque is generated when the lid is in the horizontal position. Therefore, for lids that close horizontally, the torque at closing is maximized, and for lids that close vertically, the rotary damper has the maximum torque in the horizontal position and the minimum torque at the end, so that the lid closes slowly and smoothly.

Disadvantages

Since the rotary damper is a buffer parts that uses the weight of the lid to generate viscous resistance, it does not have the power to assist in lifting the lid, so gas springs to support lifting are recommended for heavy lids. And rotary dampers use silicone oil, which tends to generate shear resistance due to its viscosity. Although silicone oil has low temperature dependence as a viscous material, the oil viscosity changes with changes in temperature. When a rotary damper is used outdoors, it should be noted that its motion closes slowly in an environment below 0°C and faster in a hotter environment.

Advantages and Disadvantages of Mounting Linear Dampers to Achieve a Close Slowly Feature on a Lid.

Advantages

Linear dampers are installed on the lid side and the enclosure side to create a damping effect, allowing the lid to close slowly. The lid can be moved lightly by opening and closing it by hand at a point far from the rotation position. In the same way, by installing the linear damper far from the center of rotation, a light load when the lid is closed can be used to dampen the lid, ensuring it closes slowly. If the enclosure side can also be fixed at a position far from the center of rotation of the lid, the damping will be stable, but consideration should also be given to the placement of the linear motion damper so that it does not get in the way when the lid is in use. Another advantage is that the linear damper can take a light load, so there is less burden on the installation side.

Disadvantages

The disadvantages of applying linear dampers to mass production are that it is relatively difficult to design the mounting position and that individual differences in the mounting position of the lid can cause the lid to close in different ways. At the phase of designing the mounting position, it may take time to find the mounting position that achieves the ideal motion, since there are any number of variations in the mounting position. Even once the mounting position is determined, it is essential to take measures such as marking the mounting surface or providing holes for mounting in advance to minimize mass production variation.

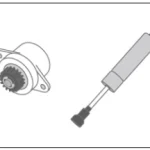

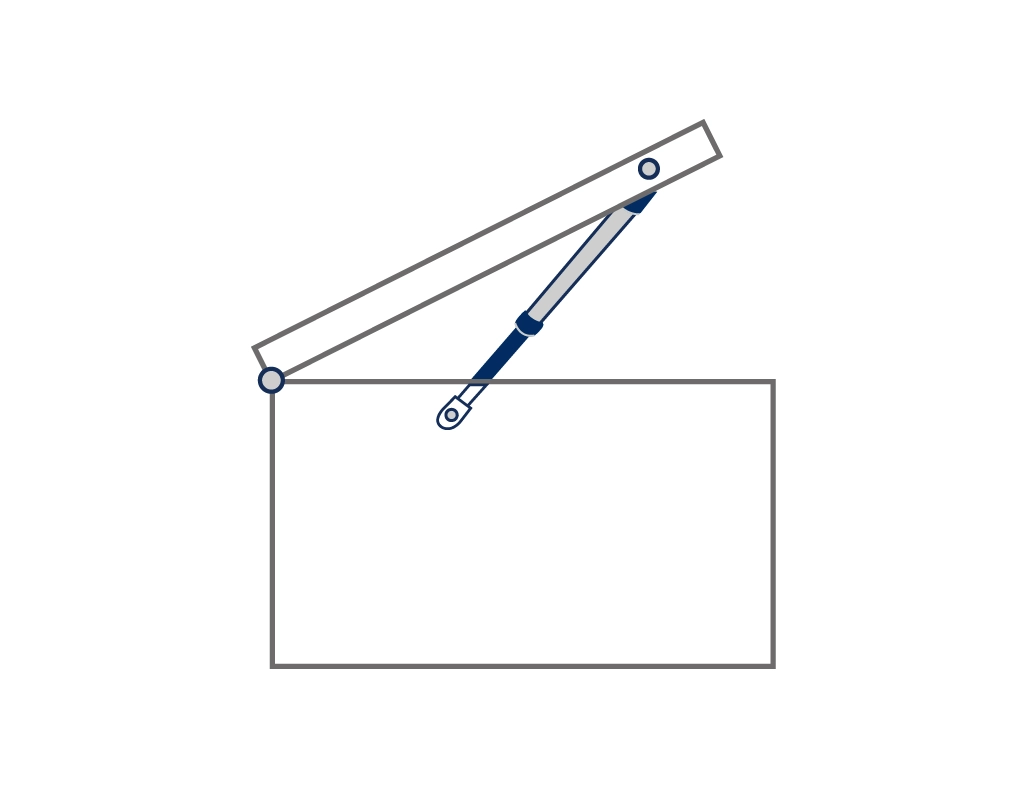

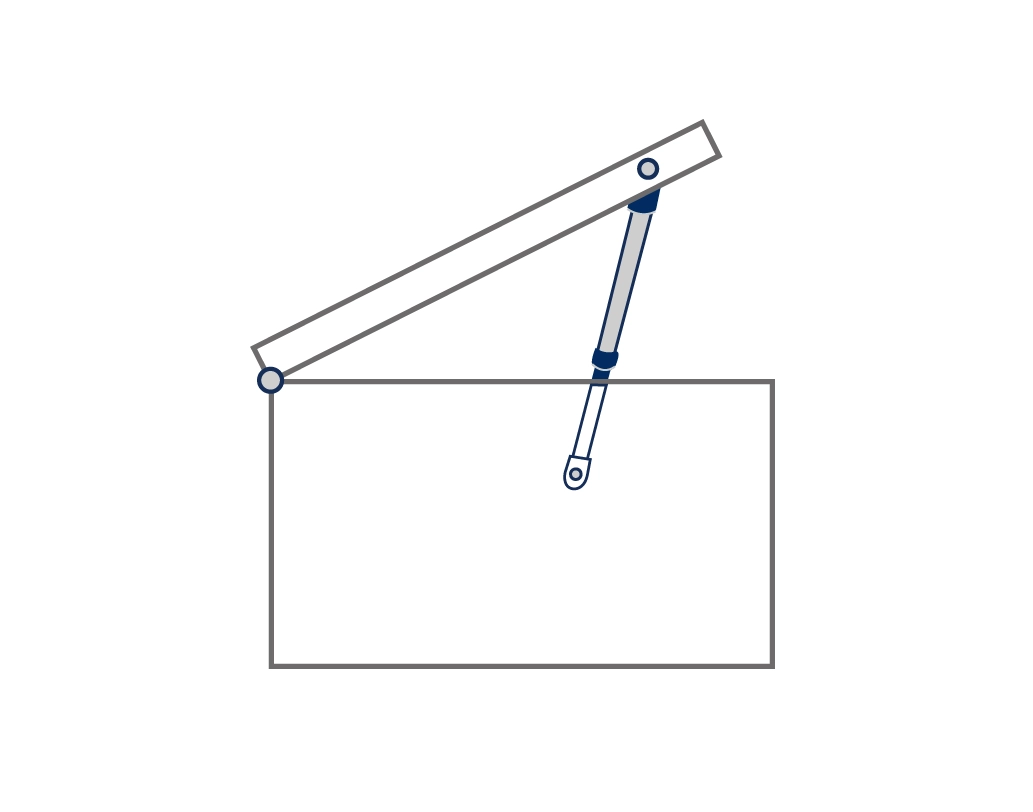

As shown in the left figure, the closer the linear damper is mounted to the enclosure of the lid from the center of rotation, the less stroke the damper has when the lid is closed, making it more difficult for the damper to exert its damping effect and close slowly. As shown in the right figure, the further away from the center of rotation, the closer the linear damper is to the center of rotation, the more effective the damper will be, but the longer the rod of the linear damper must be to maintain the required lid operating angle and ensure the lid closes slowly.

Selection Points for Buffer Parts Make Lids Close Slowly

The choice of the buffer parts depends on the weight and size of the lid, installation space, design, and other conditions.

Lid weight and size

Lid weight and size are important factors in selecting buffer parts. A small, low torque rotary damper is suitable for small, lightweight lids, while a linear damper with higher torque is suitable for large, heavy lids. The mounting position and torque of the damper must be determined taking into consideration the center of gravity of the lid.

Mounting space and design

The mounting of buffer parts greatly affects the design and functionality of the product. Rotary dampers are suitable when design is important, since they are simply assembled by fitting into the lid’s mounting area and do not detract from the product’s appearance. On the other hand, a linear damper requires an operating space for opening and closing because the rod extends and retracts. For example, linear dampers are sometimes used in luggage compartments on airplanes. They are mounted on the outside of luggage compartments so that they do not get in the way when luggage is being loaded. Since the space for the operation of the linear motion damper will be reserved on the outside of the luggage compartment, the space for luggage will be relatively small.

On the other hand, in the case of installing a linear damper on a heavy lid, the linear damper may be daringly exposed to a visible position so that the user can feel the sturdiness and safety of the product. Thus, in selecting buffer parts, it is important to consider whether design or functionality is more important.

Summary of Comparison and Selection of Buffer Parts to Make Lids Close Slowly

For lids that close slowly, rotary dampers or linear dampers are installed, and the choice must be made according to the characteristics and application of each. The required torque varies depending on the material and size of the lid, so it is difficult to make a general statement based on the weight of the lid, but the rotary dampers that TOK manufactures can be used up to 10 N・m as torque. Click here to see our lineup of rotary dampers.

Related Articles

・Rotary damper torque auto-calculation

・Tips to determine a rotary damper torque

フォームが表示されるまでしばらくお待ち下さい。

恐れ入りますが、しばらくお待ちいただいてもフォームが表示されない場合は、こちらまでお問い合わせください。