A small diameter high torque rotary damper, TD100 series, has an outer diameter of 16 mm and 3.0 N・m. In 2007, TOK started the development of TD100 high torque rotary damper for toilets markets in the Europe region. Because TOK received many requests to provide rotary dampers for use in stylish and thinner designed toilet seats in the toilet industry in the European region, and it seemed to be trending rotary dampers with a small outer diameter and high torque.

In this article, we introduce the development story and the features of TD100.

Contents

Development background of small diameter high torque rotary damper TD100

![]()

At the time of development, there was a growing demand to be better design regular toilet seats that were not bidet toilets. This was a need for a slimmer toilet seat, which inevitably required a smaller high torque rotary damper. The trend towards slim rotary dampers was doubtless, as we saw competitors of rotary dampers exhibited smaller rotary damper in diameter at the exhibition. In order to be smaller diameter of rotary dampers, a competitor had developed a new mechanism in which the rotational motion of the shaft is converted into a linear motion by a cam mechanism so that a spring force is generated. TOK also found it essential to realize the needs of its customers in the toilet industry.

TD22 and TD56 used to be applied to toilet sheets before start developing TD100, but TOK assumed that both of rotary dampers were unsuitable for slimmer toilet seats since TD22 is extremely long overall length, and TD56 is a large outer diameter of ø18 mm.

Various new mechanism had been explored as TOK for the supply of new products and prototype verification was carried out, and TOK considered the advantages and disadvantages of the new mechanism. And then, it was decided to proceed the development of a high torque rotary damper with an outer diameter of φ16 mm and a maximum torque of 3.0 N・m with a shorter length refer to the conventional design concept.

The following two issues were raised in the development of the rotary damper

・Ensure a maximum torque of 3.0 N・m with an outer diameter of φ16 mm and an overall length of around 50 mm.

・Use a material that can withstand toilet detergent for a toilet.

The solution to the above problems was constructed as follows.

Rotary damper design challenge 1: Small diameter and high torque

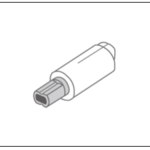

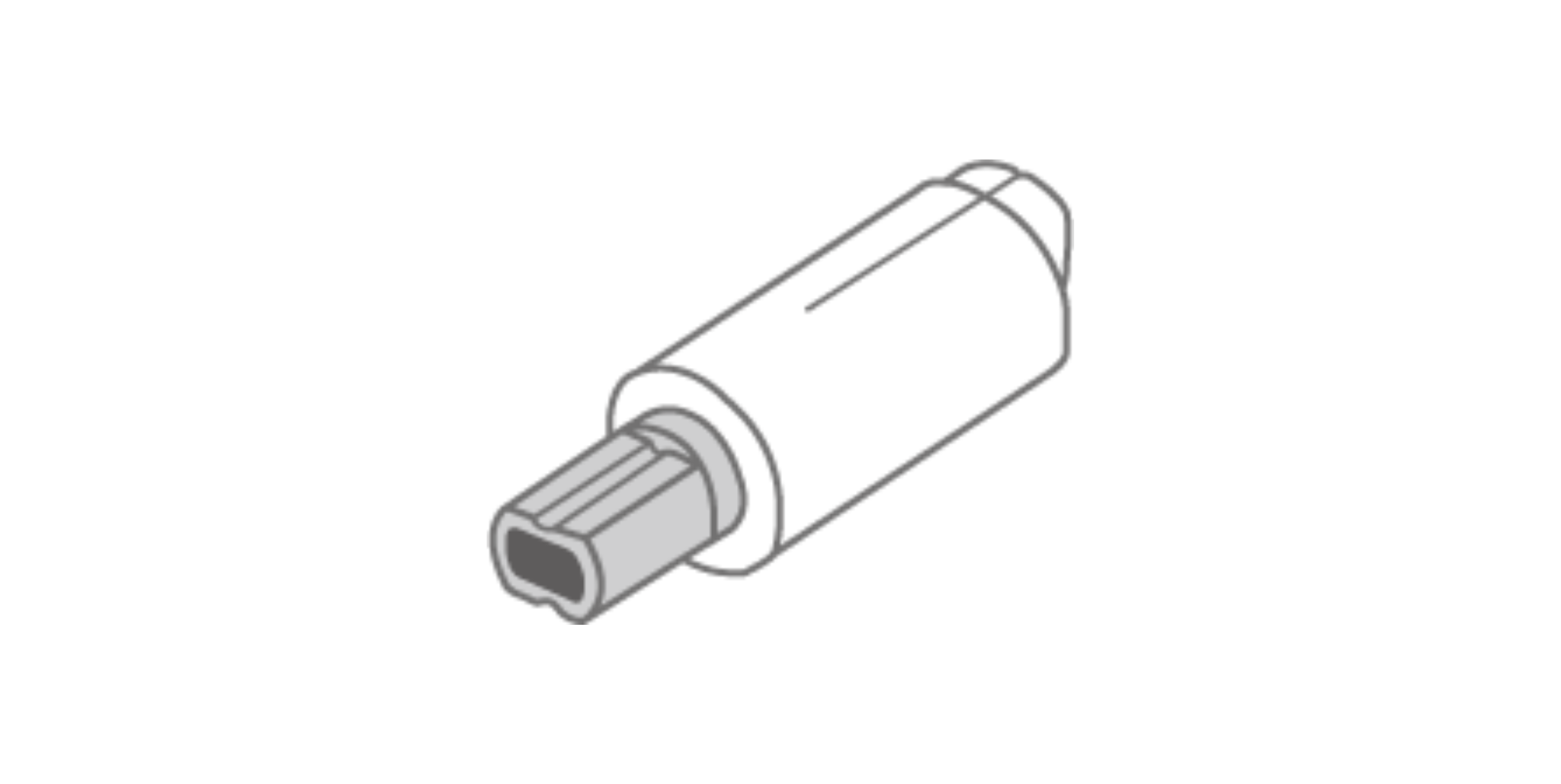

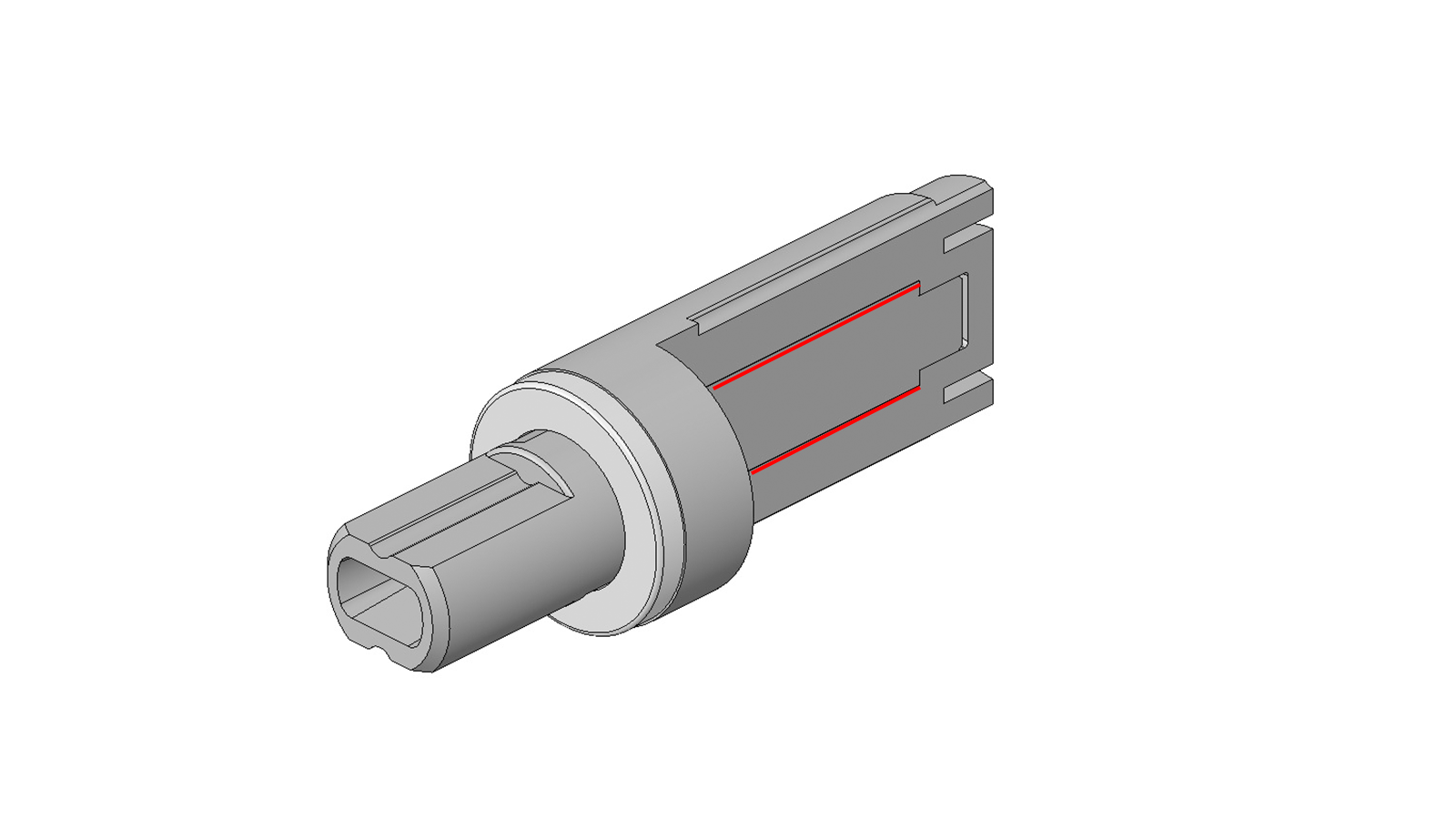

To ensure the high torque rotary damper’s damping torque, the shaft was slightly pressed fit to the bulkhead inside of the housing to eliminate the initial gap (red area in the diagram above). so that the oil flow path inside of the damper was as narrow as possible. Although the damping torque decreases in initial by easing off of the light press fit between the housing and the shaft, the shipping standard is set by considering the decrease of initial torque.

At the decision of the standard, TOK confirmed its validity through various tests, such as initial performance, durability and temperature characteristics.

Furthermore, TOK had the knowledge that the rotary damper with φ16 mm of outer diameter is higher internal pressure than the rotary damper with an outer diameter of φ18 mm in the condition of the same generating torque, and it was forced to change the sealing material. The material of the O-ring was changed to a harder material than before since the conventional O-ring would not be able to withstand durability. In addition, the parts design that is related ultrasonic welding process adopted for the rotary damper assembly was also modified not to break due to the internal pressure during operation.

Rotary damper design challenge 2: Materials that can withstand toilet applications

As the developed high torque rotary damper is designed to be installed in toilet seats and lids, it needed to be made of a material that could withstand detergent. In conclusion, a chemical resistant resin called PBT was used for the housing and cap, while zinc die-cast was selected for the shaft.

TD22, high torque rotary damper with a proven track record in toilet applications, has a die-cast housing and cap, but for TD100 was able to be applied PBT resin for the housing and cap, and to be kept chemical resistance and reduced the weight.

Summary of Small diameter high torque rotary damper | TD100 development story

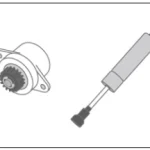

TD100 was launched as a rotary damper with a small diameter, high torque, short overall length, and a resin housing. This rotary damper can be combined with the separately developed simple detachable system SR14 to add a soft close function to the toilet seat, while the shaft on the toilet bowl can be easily detached from the toilet seat, making it easy to wipe the toilet bowl for cleaning. Please watch this video for a detailed explanation.

Please wait until the contact form is indicated.

If you cannot find the contact form in spite of waiting, please let us know from this link.