The high torque rotary damper TD22 is made up of zinc die-casting with 16.2mm of outer diameter and 3.92Nm of maximum torque. In this article, we introduce the development story of the TD22, which is an improved version of the predecessor models TD4 and TD16, which were introduced in the introductory article on the history of rotary dampers with an outer diameter of 16 mm.

Contents

Development background of small diameter high torque rotary damper TD22

TD22 is our “22nd” rotary damper. At the time of development, improved high torque rotary damper specifications began to be requested along with increased demand for rotary dampers. We assumed that the specifications were more important than its dimensions because TD22 has developed that the external dimensions correspond to those of TD4 and TD16 to keep the detent shape remains unchanged. therefore, customers can use TD22 without any changes customer’s design.

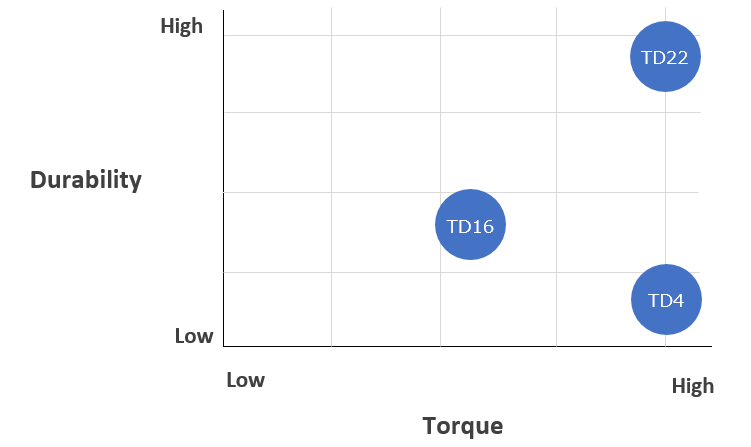

Other than the dimensions required, performance characteristics such as temperature, damping torque, and durability are important requirements for rotary dampers. Of these requirements, temperature characteristics can be supplemented to some extent by material selection, but silicone oil, the most suitable viscous material for rotary dampers, cannot be changed, so a significant improvement cannot be expected. The other two issues were torque and durability, these were challenging to improve them at the same time. This is because TD4 can support up to 3.92 N・m of torque but is not expected to be durable, while TD16 is guaranteed to open and close 10,000 times, but has a maximum torque of 2.45 N・m.

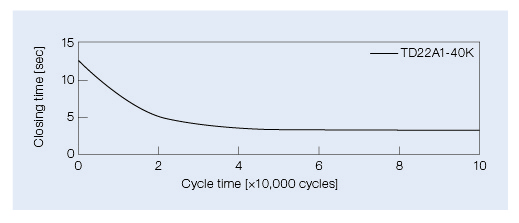

Against this background, the target for the development of TD22 was set ‘maximum torque of 3.92 N・m and durability of 100,000 cycles’.

On the other hand, when installing the rotary damper, it was ideal that no damping torque should be felt when the lid is opened. To achieve this, an essential requirement was to incorporate vanes so that the oil flow path widens when the lid is opened and narrows when the lid is closed. TOK has been using a uniquely designed ‘U-vane’ from TD4 to provide a good operating feel of the lid, and this feature had to be applied to TD22 as well.

The means of achieving development targets for the small diameter high torque rotary damper TD22

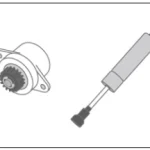

For the target “to meet the maximum torque requirement of a high torque rotary damper at 3.92 N・m and durability of 100,000 cycles with the same external dimensions as TD4 and TD16”, TD4 was the reference for the maximum torque and TD16 for the durability.

Firstly, we focused on the fact that TD4 is assembled with a caulking as the reason for the unclear durability, even though TD4 achieves the target torque. TD4 is completed by caulking the end faces of the aluminum housing, whereas TD16 is completed by caulking the ends of the stainless-steel pipe. Considering the effect of this caulking on durability, it was weak that TD4, which is made of softer material, is more vulnerable. This is because internal pressure of the rotary damper acts in the direction of loosening the caulking of the housing each time the lid is closed. For this reason, we decided to use screw fastening instead of caulking as the assembly method.

We then turned our attention to the material and shape of the individual components. TD16 has a housing and shaft made of PPS resin, which has good heat resistance and utilizes the self-lubricating properties of resin but does not have the same rigidity as metal. On the other hand, TD4 has a zinc die-cast shaft and aluminum housing, which has a certain rigidity, but not a good combination of sliding characteristics. Therefore, we used resin in areas where sliding properties should be taken into account and used zinc die-castings overall to ensure rigidity.

The target durability of 100,000 cycles was not only secured by changing the assembly method, securing rigidity through material selection and reviewing tribology properties, also reviewing the wall thickness and shape of each part in detail.

Summary of Small diameter high torque rotary damper | TD22 development story

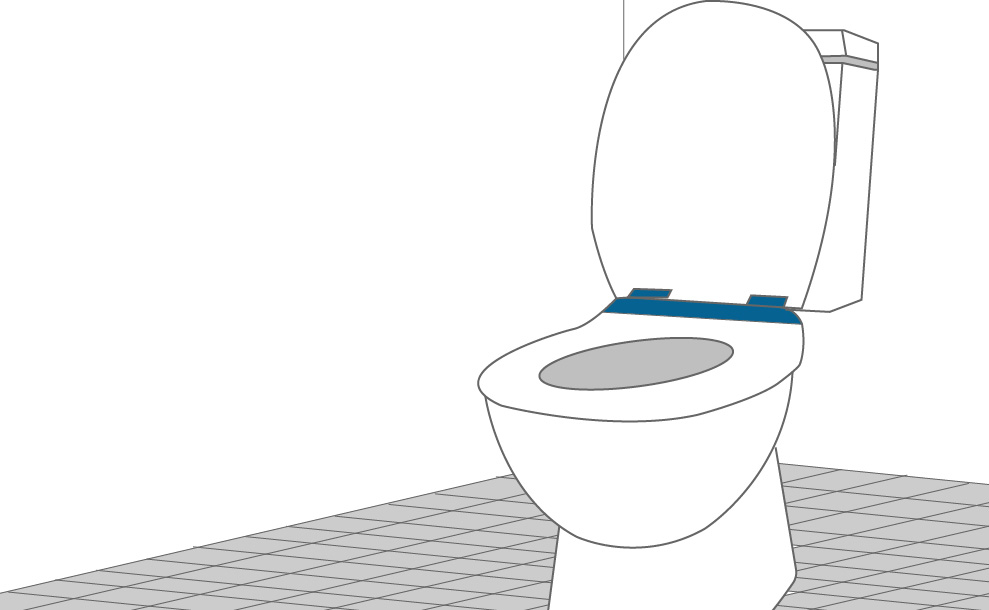

The improvements made to TD22 since its predecessor model were successful, and since its release in 1997, it is currently used as rotary dampers for piano keyboard covers. TD22 has been appreciated for its advantage in reducing lid rattling after assembly, due to the relatively long shaft and housing.

TOK has improved existing products to meet customer requirements. If the performance of the existing product is not enough, please feel free to contact us.

Please wait until the contact form is indicated.

If you cannot find the contact form in spite of waiting, please let us know from this link.