![]()

The needs for a high torque rotary damper with a 16 mm outer diameter for partial rotation angles is increasing these days.

Our best-selling rotary dampers have an outer diameter of 18 mm, but in 1990, when TOK started production of the rotary dampers, rotary dampers with an outer diameter of 16 mm were the best-selling.

Based on our records, we would like to explain why rotary dampers have an outer diameter of 18 mm have become the standard rotary damper and why the need for rotary dampers have an outer diameter of 16 mm has been increasing again in recent years.

Contents

Introduction stage of rotary dampers (Outer diameter of 16mm)

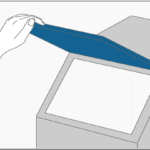

Our first product with an outer diameter of 16 mm dates back to TD4. (TOK models are numbered consecutively in the order in which rotary dampers were launched.) TD4 was developed for toilet seat applications and was the first long and high torque rotary damper. The purpose of the irregular hexagonal detent shape is stress concentration relief on the object and protection for mis-assembly.

At the time, there was no demand for a rotary damper in toilets, and toilet seats without rotary dampers had no thickness in the mounting area. Therefore, a rotary damper with as small an outer diameter as possible while ensuring the necessary torque was preferred, resulting in a long and thin shape with a diameter of 16 mm and an overall length of 90 mm.

The damper housing section of TD22 is long enough to ensure the required torque, but there is another reason for the longer shaft. It seems that this was to allow the toilet seat to have a damper function and close slowly, and to allow the long shaft of the rotary damper to act as a hinge on the toilet lid.

A successor model, TD16, was subsequently developed with improved manufacturing processes and endurance performance, and the shape of TD4 relating to installation was inherited.

However, TD16 was designed with PPS resin as the main material and a stainless steel outer cylinder to supplement the damper torque and could not meet the need for a torque of 2.45 Nm or more. So TD22 was developed with a different material and a zinc die-cast housing to meet the target specifications required by the customer and succeeded in meeting the target specification of 3.92 Nm of torque.

Growth stage of rotary dampers (Outer diameter of 18mm)

During the growth period, polypropylene resin which is low density was used for the toilet seat. The torque required for the rotary damper is now only 1.96 Nm, half of what was previously required, but the axial length had to be reduced in size due to design restrictions. This was due to the current requirement to mount the rotary damper on both the toilet seat and lid, and the need to downsize the rotary damper to fit the axial insertion space.

The axial length was halved with the downsizing, and the lack of torque was compensated for by the outer diameter, which was increased from 16 mm to 18 mm in outer diameter. This rotary damper with an 18 mm outer diameter became established and became the standard rotary damper shape in use.

Maturity stage of rotary dampers (Outer diameter of 16mm)

![]()

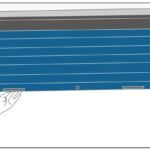

In recent years, rotary dampers have been installed in toilets not only in Japan but also in the world. As most world toilet materials are made of urea resin which is low density, so rotary dampers require a relatively high torque. In particular, European toilets also place great emphasis on design, so small and high torque rotary dampers were needed that could accommodate slim designs.

TD100 was created by utilizing the design of a rotary damper with an outer diameter of 16 mm, which had a proven track record in the introduction stage, and the design know-how gained through repeated improvements. Later, TD129 was developed with a die-cast housing to accommodate even higher torques.

Summary of the needs for high torque and 16 mm outer diameter rotary dampers

Rotary dampers have changed to meet market needs, but innovation in rotary dampers alone does not produce good products. It is important to balance the materials with the product in which the rotary damper is mounted, so that both can be used for a long time without damage. The size of the rotary damper must be changed in the axial direction or outer diameter to match the torque, and the shape must be optimized.

With our design know-how, we can also provide customized solutions tailored to the performance you require. Please contact us if you are interested.

Related articles

Small diameter high torque rotary damper | TD129 development story

Please wait until the contact form is indicated.

If you cannot find the contact form in spite of waiting, please let us know from this link.