Our heavy-duty rotary damper for aircraft was developed for use in aircraft lavatory doors. In general, aircraft components are difficult to control and maintain frequently, and rotary dampers had to be designed so that their performance would not influence due to changes in atmospheric pressure.

In other words, the high durability and ability to support changes in atmospheric pressure not found in conventional rotary dampers were required as specifications specific to aircraft applications, so TOK began the development of a new heavy-duty rotary damper for aircraft and it was mass-produced.

In this article, we will introduce the development story and features of SR3 high-end heavy-duty rotary damper, which is highly durable and can be responsible changes in atmospheric pressure.

Contents

- Background of the development of SR3 heavy duty rotary damper for aircraft

- Rotary damper design challenge 1: Long life

- Rotary damper design challenge 2: Pressure-adjusting function

- Rotary damper design challenge 3: Shortening lead time

- Rotary damper design challenge 4: Mounting shapes

- Summary of Heavy duty rotary dampers | Development story of aerospace rotary damper

Background of the development of SR3 heavy duty rotary damper for aircraft

Rotary dampers have been conventionally installed in the aircraft lavatory doors to close the door softly. When your hand is released from the door, the spring and the rotary damper functions to close the door slowly and quietly without making any noise to the surrounding environment. The development of SR3 was triggered when the customer obtained information about the discontinuation of a rotary damper manufactured by another company and asked us whether we could develop a new rotary damper. We repeatedly developed prototypes while applying our own expertise, and took on the challenge of developing a new product SR3 with high durability and a pressure-adjusting function that responds to changes in atmospheric pressure.

The following specifications were required during the consideration stage.

・Torque (1.0 Nm)

・Long life (Durable to open and close 300,000 times)

・Pressure adjusting function to eliminate the effects of changes in atmospheric pressure

・Shortening lead time

・Appearance dimensions that can be recombined with existing products.

In these requirements, long life, pressure-adjusting function, shortening lead time, and mounting shapes were highly challenging problems. In addition, inside of the existing products design had not to be copied in order to prevent patent infringement.

In the next section, we will explain each of these design issues in detail.

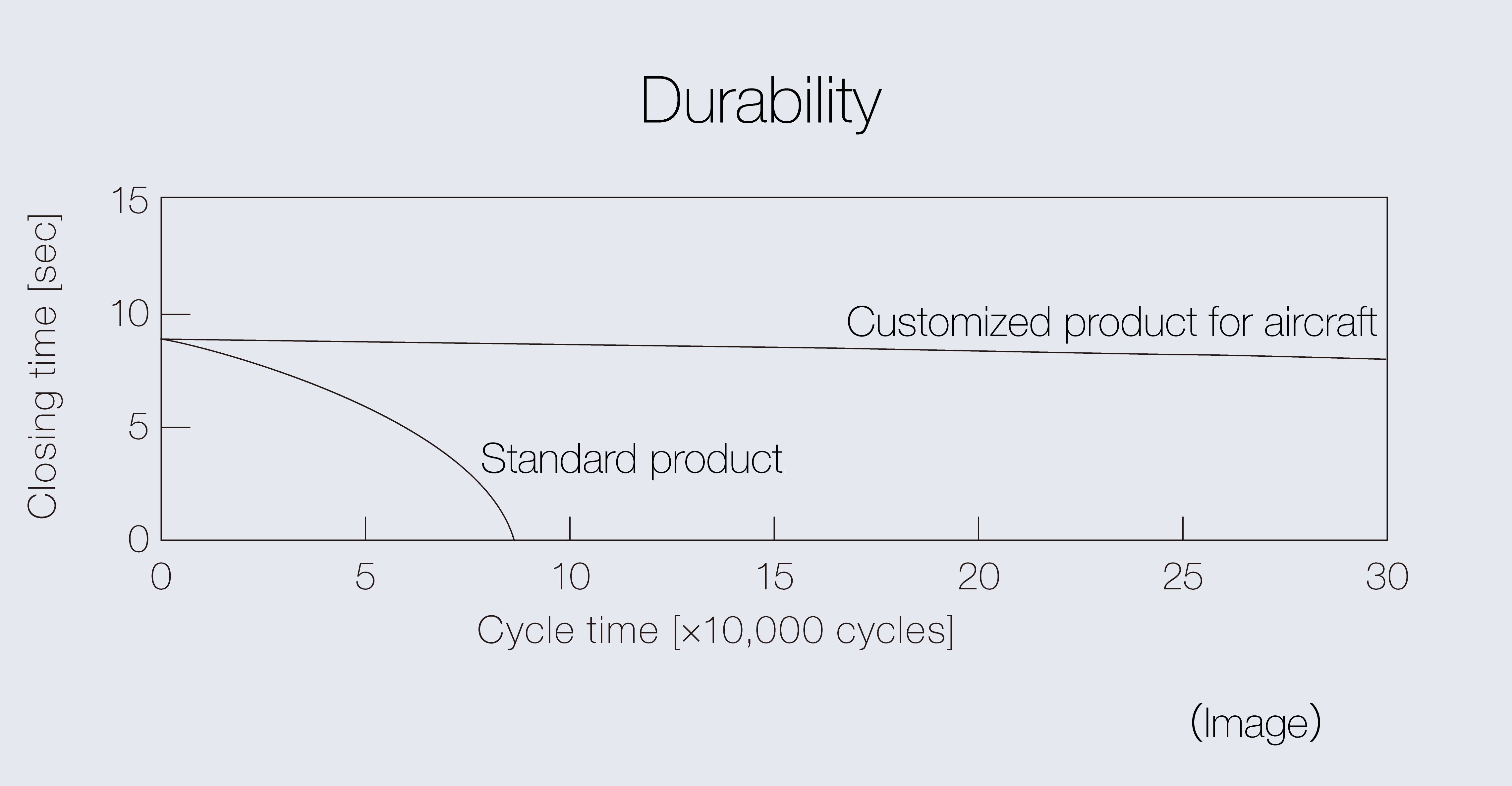

Rotary damper design challenge 1: Long life

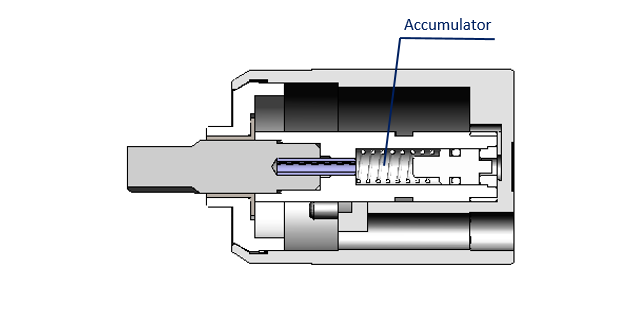

The durability standard for rotary dampers manufactured at TOK is durable to open and close 50,000 times and the requirement of opening and closing 300,000 times is six times the standard rotary damper. In the prototype phase, TOK had been experienced by durability test while changing the shape of parts. The most effective way to improve the durability of rotary dampers is to prevent accelerated wear of the internal mechanism. In conventional die-cast rotary dampers, wear is prevented by intervening sliding parts only where wear of the internal mechanism is significant. In the newly developed heavy-duty rotary damper for aircraft, durability has been improved by interlacing sliding members at all sliding points where wear may occur. Furthermore, an accumulator function (a function to release oil by increasing the internal volume of the damper when the oil pressure exceeds a certain level) is incorporated to automatically optimize the internal pressure of the damper even when the door is forcibly closed and this was a factor in achieving long life.

Rotary damper design challenge 2: Pressure-adjusting function

You have probably already experienced that the atmospheric pressure in the cabin during flight is different from that on the ground. The rotary damper is affected by atmospheric pressure in the same way, even if it is not a problem on the ground, but the residual air in the damper expands in the sky, increasing the rotational resistance of the rotary damper and slow closing the door, or the rotary damper housing cracks and the door loses its damper function. To avoid such concerns, a pressure-adjusting function was needed to maintain the internal pressure of the rotary damper at the same level as at ground level, which could be provided by the accumulator function described above.

In order to introduce the accumulator function, it was necessary to change the design of the oil flow paths inside the damper so as not to infringe on patents owned by another company while maintaining the same functionality as existing products as much as possible. In order to realize a superior pressure-adjusting mechanism, we analyzed the oil flow of the existing product and spent four months considering the mechanism through trial and error.

Rotary damper design challenge 3: Shortening lead time

The existing product had all parts manufactured by cutting, but TOK has shortened the lead time by producing some parts using a mold. While cutting parts need to be manufactured one at a time, mass production using a mold enables the production of a large number of parts with complex shapes in a short period of time, thus contributing greatly to lead time reduction. However, the same materials used for cutting cannot be used for mold production. In the process of considering alternative materials, there was a chain of failures. A part would break, and when it was repaired, another part would break again, and it took a year to optimize the wall thickness and materials and successfully open and close 300,000 times.

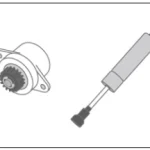

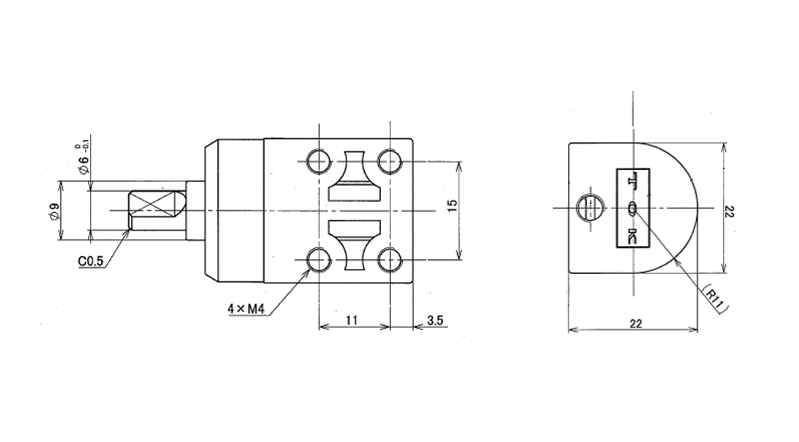

Rotary damper design challenge 4: Mounting shapes

Since the external shape was required to be the same as the existing product, the mounting shape also had to have four screw holes on the bottom surface. The screw holes needed to be a certain depth to secure the fastening force of the screws, which limited the space inside required for the rotary damper. Although it became difficult to design the damper to secure sufficient torque, we succeeded in making the mounting shape equivalent to that of existing products by holding the damper chamber as wide as possible and optimizing the wall thickness.

SR3 introduced here can be also seen in this video.

Summary of Heavy duty rotary dampers | Development story of aerospace rotary damper

In this article, we introduced the development story of the rotary damper for aircraft. For rotary dampers, the application to aircraft has more demanding specifications than ever before, so there was a considerable amount of trial and error before the design was finalized. SR3 rotary damper, which was born out of this hard work, features long life and the ability to support changes in atmospheric pressure, features that were not available before.

As in the case of this project, it is often possible to achieve a new design even when conventional products cannot meet the requirements, so if you can not find your desired product in a standard product, please feel free to contact us.

For the initial design consideration, please use the page for torque calculation. If you have any questions, please contact us using this form.

Please wait until the contact form is indicated.

If you cannot find the contact form in spite of waiting, please let us know from this link.